Contact Us

- WhatsApp:

- Email:

- Tel:

- Phone:

News

-

Sign Off on Success: Nigeria's 1-ton Tapioca Powder & Garri Production Line from Henan Jinrui

Sign Off on Success: Nigeria's 1-ton Tapioca Powder & Garri Production Line from Henan Jinrui

-

Congolese Client Orders 4-Ton Fully Automatic Fufu Flour Processing Line From Henan Jinrui

Congolese Client Orders 4-Ton Fully Automatic Fufu Flour Processing Line From Henan Jinrui

-

Liberian customers ordered garri processing machines for the third time

Liberian customers ordered garri processing machines for the third time

-

3TPD Garri production line is about to be shipped to Nigeria

3TPD Garri production line is about to be shipped to Nigeria

-

Cassava processing machines purchased by Philippine customers were shipped

Cassava processing machines purchased by Philippine customers were shipped

Cassava Processing Project

How to dry sweet potato starch, machine drying or manual drying?

How to choose the drying method for the production of sweet potato starch? This article compares the two drying methods from drying efficiency, drying cost and the quality of sweet potato starch after drying in details.

The similarities and differences between paddle washer and rotary washer—starch making equipment

Henan Jinrui designed two washing equipments, they are paddle washer and rotary washer. The following will introduce the similarities and differences between them.

What machine do you use to grind the cassava into flour?

There are two common cassava flour milling machines on the market, one is a complete set of cassava flour milling equipment, and the other is a combination of "cassava slicer + cassava crusher".

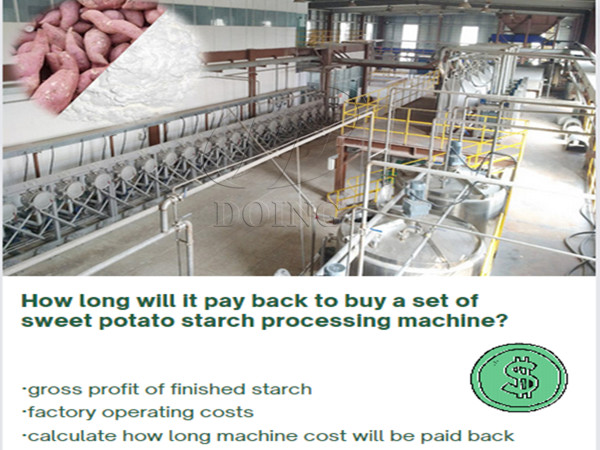

How long will it pay back to buy a set of sweet potato starch processing machine?

Generally, paying back machine cost needs take into account the following factors: raw material buying costs, factory operating costs and the price of the final sold starch. Henan Jinrui can help you do free profit analysis.

How does the cassava chips machine operate?

The cassava chips machine is mainly used for cassava chip processing. In order to make the cassava chips machine give full play to its performance and bring you high economic benefits, Jinrui will tell you how the cassava chips operate.

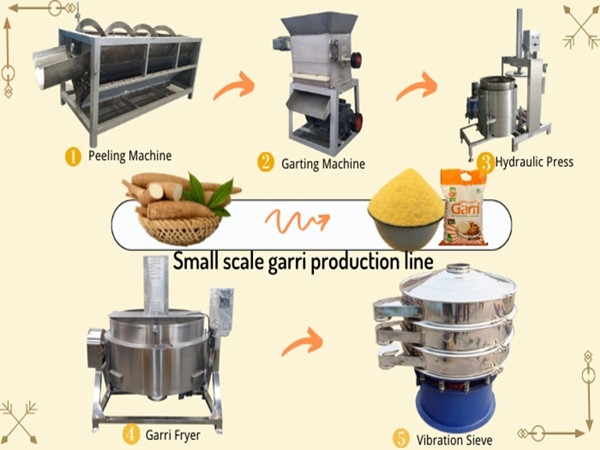

What will it take me to set up a mini garri processing plant?

For a mini garri processing project, there are machine costs, shipping costs, workshop building costs, etc. Machine cost is about 20,000$ dollars, then add shipping, workshop building, etc. Clients should prepare a budget of about 30,000$ dollars.

The methods of potato starch extraction

There are two production methods of potato starch: traditional semi-automatic processing method and modern fully automatic processing method. This article will compare the two methods in detail.

How much does it cost to venture into a potato starch processing business?

Many novice investors will wonder about the question of "how much does it cost to venture into a potato starch processing business". This article answers from the following aspects: potato starch processing plant construction cost, production raw mat...

How to increase potato starch yield?

In order to increase the output of potato starch, we can start from the following two aspects, one is to choose potatoes with good quality and high starch content, and the other is to introduce mature and advanced potato starch processing machinery.

Leave a message about Cassava production technology support,make cassava flour,starch,garri technology

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour