What will it take me to set up a mini garri processing plant?

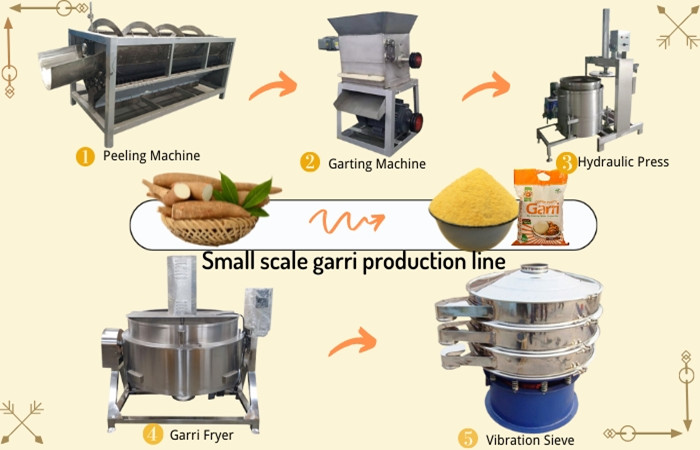

Garri processing can be divided into 7 steps include cleaning, peeling, grating, fermentation, dewatering, frying, and sieving. Then locals can get final garri production. In west Africa, some locals process garri by manual which is low capacity and toilsome. There will appear supply falls short of demand situation, locals start to use machines to replace manual processing to promote capacity and garri quality.

Mini garri processing project

Mini garri processing project

Henan Jinrui Food Company is a cassava processing machine manufacturer with over 10 years of experience, there are kinds of capacities cassava processing machines to meet clients’ requirements. For garri machines, Henan Jinrui Food Company machines can process garri processing machines from 1ton output per day to 1-ton output per hour with the price of about 20,000$ dollars to over 200,000$ dollars FOB in Qingdao, China.

For a mini garri processing project, there are machine costs, shipping costs, workshop building costs, etc. Machine cost is about 20,000$ dollars, then add shipping, workshop building, etc. Clients should prepare a budget of about 30,000$ dollars. Moreover for workshop building, if locals need it, we can provide workshop building workshop layout and machine layout according to the exact topographic map.

If you also have any ideas or want to venture into a garri processing project, you can send us a message about which kind of machine u want. We will feel free to get your inquiry.

Leave a message about What will it take me to set up a mini garri processing plant?

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour