Contact Us

- WhatsApp:

- Email:

- Tel:

- Phone:

News

-

Sign Off on Success: Nigeria's 1-ton Tapioca Powder & Garri Production Line from Henan Jinrui

Sign Off on Success: Nigeria's 1-ton Tapioca Powder & Garri Production Line from Henan Jinrui

-

Congolese Client Orders 4-Ton Fully Automatic Fufu Flour Processing Line From Henan Jinrui

Congolese Client Orders 4-Ton Fully Automatic Fufu Flour Processing Line From Henan Jinrui

-

Liberian customers ordered garri processing machines for the third time

Liberian customers ordered garri processing machines for the third time

-

3TPD Garri production line is about to be shipped to Nigeria

3TPD Garri production line is about to be shipped to Nigeria

-

Cassava processing machines purchased by Philippine customers were shipped

Cassava processing machines purchased by Philippine customers were shipped

Cassava Processing Project

How to select cassava starch production line ?

Companies need to choose the right equipment for high quality cassava starch production. Specifically, the techniques for selecting a cassava starch production line processing facility include the following aspects.We can give the suitable suggestion...

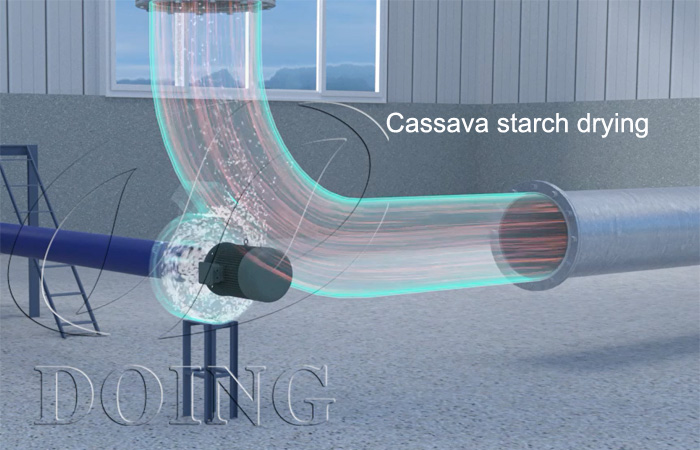

How to dry starch ?

The following part will explain how to dry starch by flash dryer. Flash Dryer is the ideal equipment for starch production.Flash dryer is especially designed for starch production, which could ensure complete dryness and product refining,is a good ch...

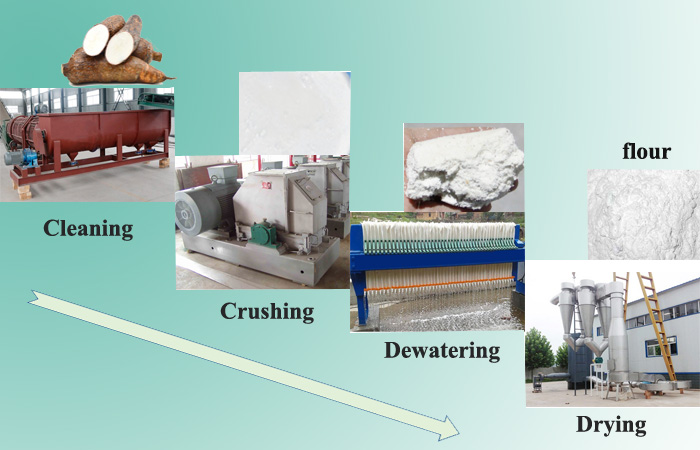

Method of processing cassava flour

Method of processing cassava flour mainly includes cassava washing and cleaning,cassava crushing,de-sanding and dehydrating,cassava flour cake milling,cassava flour drying,flour sieving and packing.This is our method of processing cassava flour,the m...

What's the process for extraction of starch from cassava ?

Many people want to build a factory to process cassava starch, but they have no idea of the process used for extraction of starch from cassava. Now the next will introduce the process for extraction of starch from cassava in detail.

Cassava processing machine cost

Cassava processing machine cost mainly decided by the cassava processing capacity and the cassava production products(starch, flour, garri) type and quality.There are many influencing factors for cassava processing machine cost.

How is tapioca extracted from cassava ?

With the research of how is tapioca extracted from cassava, mounts of starch processing factories emerged worldwide.Doing Company can give you the best answer for how is tapioca extracted from cassava and tapioca extract machine,this is the introduct...

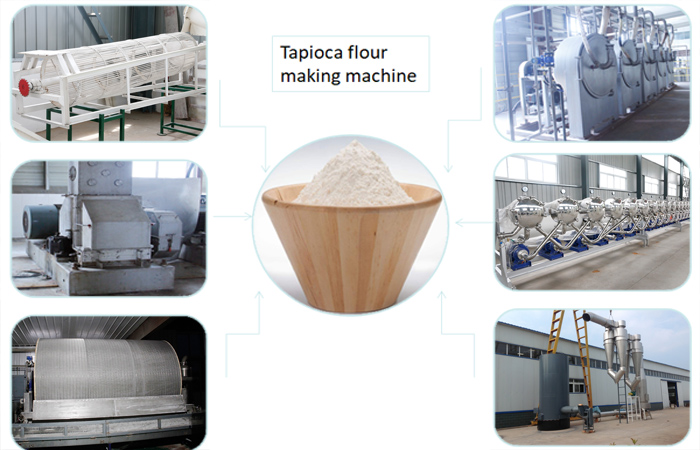

How cassava processing into tapioca

The introduction about how cassava processing into tapioca.It includes cassava washing and cleaning, cutting and crushing, tapioca extraction and concentration, dewatering and milling, tapioca drying, tapioca sieving and packing.

How to process cassava into flour ?

Cassava flour is made by peeling the whole root, then dried and ground.It has amount of dietary fiber and is gluten-free. It is neutral and mild in flavor,so it is important to know how to process cassava into flour. The following article will explai...

How is tapioca made from cassava ?

Tapioca is a kind of starch made from cassava. The production process about how is tapioca made from cassava is actually a physical separation process,Doing Company can manufacturer and shipment tapioca processing machine to you,answer your question ...

Leave a message about Cassava production technology support,make cassava flour,starch,garri technology

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour