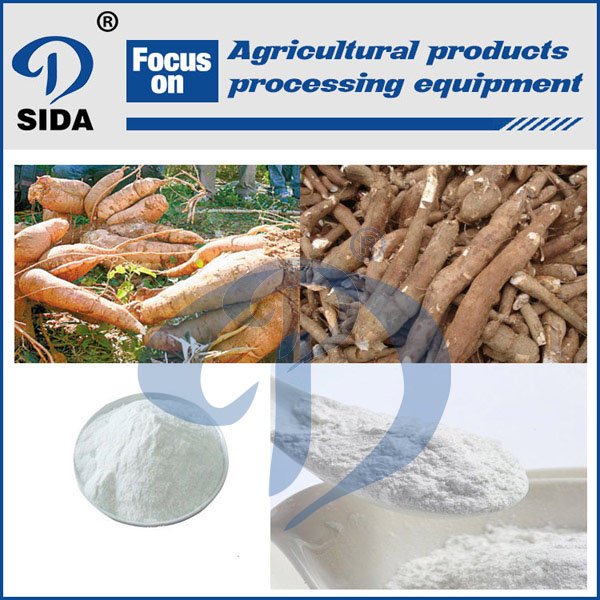

Cassava starch processing machine details

Wet cassava starch is produced by traditional cassava processors either as a direct product or as a by-product resulting from cassava processing into other products such as gari, fufu e.t.c. Post-harvest loss is high for cassava roots due to the inadequacy of the traditional processing method and inability to convert cassava into less perishable products. To reverse this trend, there is a need to mechanize cassava processing. The Federal Institute of Industrial Research, Oshodi (FIIRO) has developed and perfected the process technology for production of cassava starch useful for various applications in the user industries. In Nigeria, mechanized cassava processing is still on the developmental stage and the potential is very high.

Cassava and cassava starch

MARKET DEMAND

There is high demand for cassava starch in Nigeria. It is widely used in industries such as: textile, pharmaceuticals, oil drilling, paper and packaging, gum and adhesives, chemical and household products manufacturing, battery, drinks and beverages, foods and so on. The desire to conserve foreign exchange and reduce import dependency is the driving force for demand for cassava starch especially as regards its partial substitution for corn starch in user industries. The demand for cassava starch in Nigeria is in excess of 350,000 tons per annum. The current domestic production capacity to meet the estimated demand for cassava starch is less than 20 per cent. The current price/tonne (2013) of cassava starch ranges between N150, 000 – N180, 000.

Food made of starch

PRODUCTION PROCESS

The basic unit operations in cassava flour production from fresh cassava roots are:

Sorting and Weighing:

The tubers are sorted to select the wholesome roots for production. The tubers are then weighed.

Peeling: The weighed cassava roots peeled manually to reduce high peeling loss associated with mechanical peelers due to irregular shape of cassava root.

Washing: Peeled root is washed with sufficient quantity of potable water to remove sand, dirt and other contaminants.

Grating: The root is grated to cassava mash.

Detoxification: The cassava mash is detoxified mechanically in a mash agitator for a certain time to eliminate the toxic hydrogen cyanide present in cassava.

Dewatering: The moisture content of the mash is reduced mechanically to about 50% to prepare for drying operation.

Granulation: The resultant cake from dewatering process is disintegrated into fine granules using hammer mill.

Drying: Granulation process is followed by drying of operation to produce cassava flour of desired quality.

Milling: The flour obtained is milled to desired particle size.

Sieving and Packaging: The flour is sieved and packaged appropriately.

cassava processing machines

RAW MATERIAL, SUPPLIES AND UTILITIES

Fresh cassava root is the only raw material for production of Cassava Starch. Cassava is grown in almost all the states in Nigeria and Nigeria has been rated the highest producer of cassava in the world. The major item of supplies is the packaging materials. Others supplies requirements include factory wears (overall, hand gloves, factory shoe, nose mask), cleansing agents, disinfectants, etc. Electricity, diesel (for generator and project truck), Low Pore Fuel Oil (LPFO) for firing the flash dryer, and water are the major utilities requirements.