Cassava chips slicer

Date:

Date:

June 27, 2019

- WhatsApp:

- Tel:

- Phone:

- Email:

With the development of Africa economy, mechanized production is encouraged to enter the field of processing raw crops, to save labor work and improve working efficiency. Especially in cassava tubers production, large quantity of raw tubers are wasted because of its low working efficiency caused by human processing, people starts to pay more attention to mechanical process. Cassava chips slicer is one kind of equipment that process cassava into slice for easier drying and storage. This equipment is welcomed by small farmers for pre-treatment of raw material, which avoid tubers being corrupt.

Cassava

Cassava chips slicer machine consists of input hopper, slicer and output conveyor. Firstly cassava tubers are put into the slicer machine through hopper, and then cassava chips will come out from outlet of slicer and fall down to the belt conveyor. Cassava chips slicer machine can cut full cassava tubers into chips with thickness 1-5cm. By adjustment of knife inside, one can get cassava chips with the thickness he wants.

Cassava chips slicer

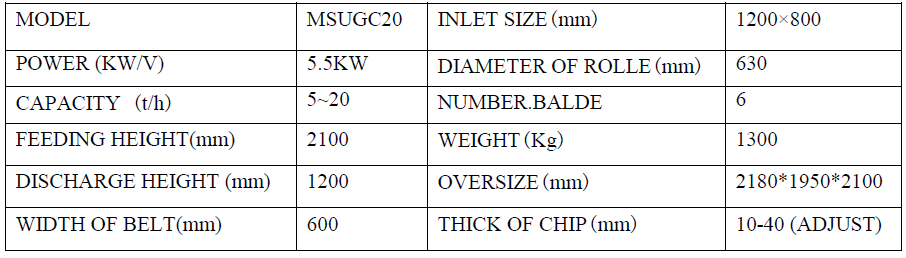

Main technical parameters of cassava chips slicer are as bellow:

In normal cassava chips processing plant, cassava chips slicer is one of the key equipment. Besides, cassava cleaning machine, cassava washing machine and cassava peeling machine will be furnished if the user has high requirements for cassava cleanness before slicing. What's more, to achieve the purpose that cassava chips can be dried in shorter time and easier for storage, cassava chips drying machine is required in big capacity processing plant.

Cassava chips slicer machine with dry cleaner

Cassava chips slicer has advantages of easy operate, simple structure, low power consumption, and more important with affordable price. It is not only suitable for small businessman, wholesaler and farmers but also good choice for big cassava chips processing factory.Leave a message about Cassava chips slicer

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour