How to Choose Tapioca Starch Processing Machine with Limited Capital to Cater for Both Farmers and Market?

For farmers and small entrepreneurs, investing in a tapioca starch processing machine presents a critical challenge: balancing limited funds with the need to meet both on-ground operational realities and stringent market standards. The right cassava processing equipment must be affordable and adaptable for the farmer, yet efficient and high-performing for the market.

In this guide, Henan Jinrui will break down how to select a tapioca starch processing machine that successfully bridges this gap, focusing on practical solutions for budget-conscious buyers.

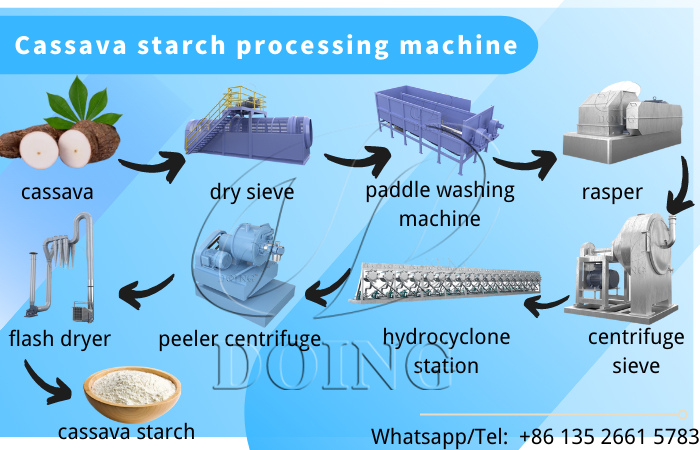

Tapioca starch processing line

Tapioca starch processing line

Meeting Farmer Needs: Machine for Budget & Mobility

To launch a viable tapioca starch processing business with limited capital, the machine you choose must solve core on-farm challenges: tight budgets and difficult logistics. Your selection should directly cater for farmers' immediate, practical realities.

1. Choose a Flexible, Scalable Configuration

Your initial investment must be manageable. Choose a customized tapioca starch processing machine that is modular, allowing you to start with an affordable core setup and add capacity later. For example, Henan Jinrui provides farmers with flexible, scalable equipment configuration, enabling you to begin processing starch and reinvest profits for future expansion—a smart strategy for farmers with limited capital.

2. Choose a Mobile, On-Site Solution

If transport costs are prohibitive, your machine must be movable. Choosing a mobile tapioca starch processing machine—like trailer-mounted units from Henan Jinrui—allows you to bring processing directly to different farm clusters. This slashes logistics costs, processes fresher roots for higher yield, and maximizes profitability, effectively helping you cater for decentralized production needs.

Cassava starch processing equipment

Cassava starch processing equipment

Meeting Market Demands: Equipment for High Yield & Quality

To succeed commercially, the tapioca starch processing machine you choose must deliver high yield and premium quality to cater for market demands.

1. Select for High Extraction Efficiency

Profitability depends on starch recovery. Choose a machine designed for maximum extraction. For example, Henan Jinrui's line uses a grater with a 98% crushing rate, paired with efficient centrifugal sieves and hydrocyclones, to ensure you get the highest return from your raw material—vital for success with limited capital.

2. Choose Advanced Refining for Premium Quality

Starch purity defines market value. You should choose tapioca starch processing machine with multi-stage purification device. Henan Jinrui's equipment, with its centrifugal sieves and multi-stage hydrocyclones, removes impurities to consistently produce starch exceeding 22° Bé—the standard for premium markets. This guarantees a better return on your investment.

Cassava starch processing line

Cassava starch processing line

The Smart Choice for Your Growing Business

Selecting the tapioca starch processing machine is a pivotal decision that defines your path forward. It’s about finding a solution that does not force you to choose between supporting farmers today and competing in the market tomorrow. The right equipment should be both affordable and mobile to meet on-farm realities, and efficient and precise to ensure commercial-grade starch quality.

Henan Jinrui provides precisely this dual solution: affordable and mobile cassava processing machines for farmer’s needs, integrated with the efficient, high-yield starch processing technology required for market’s growth. This means you can start small and local without compromising on your ability to produce starch that commands top market prices. We offer not just individual machines, but a cohesive, scalable processing plant strategy.

Ready to explore the ideal tapioca starch processing machine configuration for your budget and market goals? Contact Henan Jinrui today to get a free configuration plan and a quote tailored to your farm size and market targets.

PREV:How Much Starch Can You Extract from One Ton of Potatoes? And How to Maximize Your Yield

NEXT:Cassava processing industry in Ondo State creates more job opportunities for locals

Leave a message about How to Choose Tapioca Starch Processing Machine with Limited Capital to Cater for Both Farmers and Market?

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour