How Much Starch Can You Extract from One Ton of Potatoes? And How to Maximize Your Yield

Under typical commercial processing conditions, the potato starch extraction rate generally ranges from 12% to 18%. This means that from one ton (1,000 kg) of raw potatoes, you can expect to produce approximately 120 to 180 kilograms of pure, dry starch.

However, hitting—or better yet, exceeding—the higher end of this range is not automatic. The variance is primarily dictated by three factors: potato variety (high-starch cultivars are essential), cultivation conditions, and, most critically, the configuration and efficiency of your potato starch processing machines. Modern, optimized processing lines are engineered to minimize starch loss at every stage. Let’s explore the key machines that are pivotal for achieving a high potato starch extraction rate.

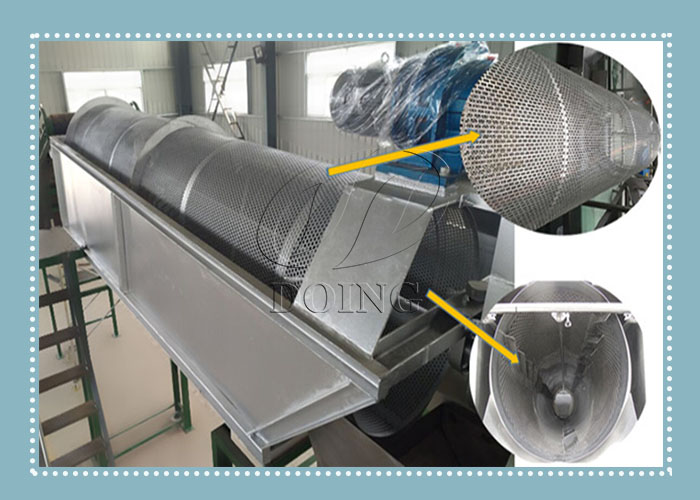

1. Efficient Potato Cleaning and Washing Machines:

The journey to high yield of potato starch begins with thorough cleaning. Soil and debris not only contaminate the final product but can also abrade and damage starch granules during processing if not removed. A modern rotating drum washer or a hydraulic destoner uses precisely controlled water pressure and mechanical action to remove impurities with minimal potato skin damage. This gentle yet effective cleaning prevents starch from being washed away prematurely with the mud, preserving your potential yield from the very first step.

rotary washing machine

rotary washing machine

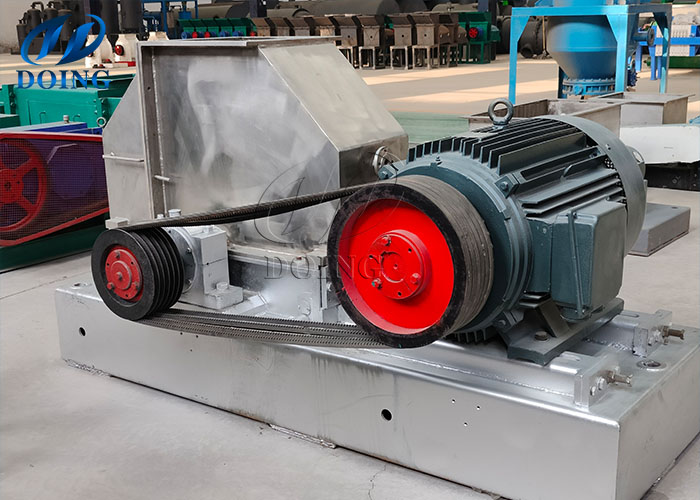

2. High-Efficiency Potato Grinding (Rasping) Mill:

This is arguably the most crucial stage for yield. The goal is to rupture as many potato cells as possible to release the starch granules. A superior potato starch rasping machine employs ultra-sharp, high-speed rotating rasps against a static screen. The key parameter is the fineness of the grind. Advanced models achieve a pulp particle size of less than 1 mm, creating a homogeneous mash that maximizes starch release. In contrast, coarse grinding leaves starch trapped inside unbroken cells, which can lead to immediate yield losses of 10% or more.

potato rasper

potato rasper

3. Potato Starch Refined Separation and Extraction System:

After grinding, potato starch must be separated from the fibrous pulp (potato residue). This is where multi-stage, precision separation makes the difference. A centrifugal sieve station uses centrifugal force and fine screens to separate starch milk from the fiber with high efficiency and low water consumption. Following this, a hydrocyclone station performs the magic of purification. Utilizing hundreds of small-diameter hydrocyclones in a cascade, it separates starch from remaining fine fibers and soluble proteins based on density differences. The purity of the starch milk after this stage is exceptional, directly leading to a higher yield of premium-grade starch.

hydrocyclone stations

hydrocyclone stations

4. Advanced Potato Starch Dewatering and Drying Machines:

Finally, recovered starch must be dried without loss. A vacuum filter de-waters the wet starch cake to a low moisture content efficiently. Subsequently, a flash dryer exposes the moist starch to a controlled stream of hot air for mere seconds. This rapid process ensures the starch is dried to a precise moisture level (typically below 20%) without gelatinizing it, preserving its functional properties and final weight.

In summary, the actual answer to “how much starch can a ton of potatoes produce?” is determined by your machinery. Investing in a coherent line of modern potato starch processing machines—from gentle washing and intensive rasping to precision separation and gentle drying—is the single most effective strategy to push your extraction rate toward the optimal 18% or beyond.

We, Henan Jinrui, specialize in designing and supplying complete, high-yield potato starch processing lines. If you are serious about maximizing your starch yield and ROI, contact us for a tailored technical proposal and more data-driven insights. Let's turn your potatoes into maximum profit!

PREV:Nothing

Leave a message about How Much Starch Can You Extract from One Ton of Potatoes? And How to Maximize Your Yield

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others