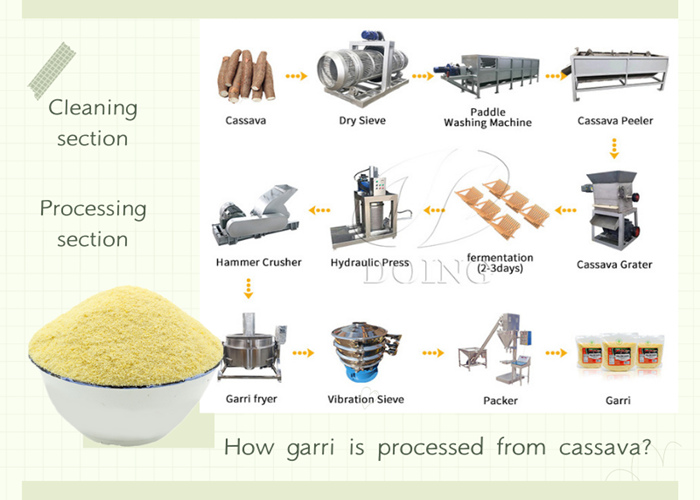

How garri is processed from cassava?

Cassava processed products generally have three types: garri, cassava flour, and cassava starch. Garri processing is the easiest project to start with, and the garri processing machine will be much cheaper. How garri is processed from cassava, let me introduce it to you.

How garri is processed from cassava?

How garri is processed from cassava?

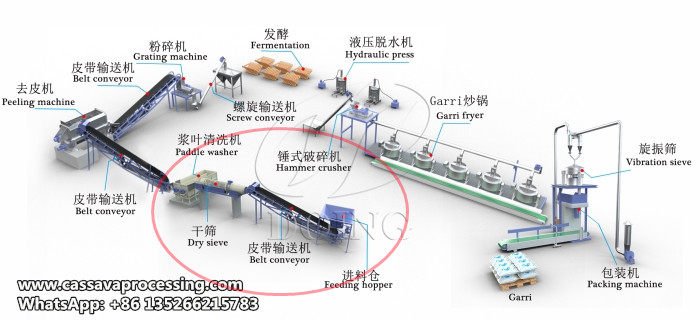

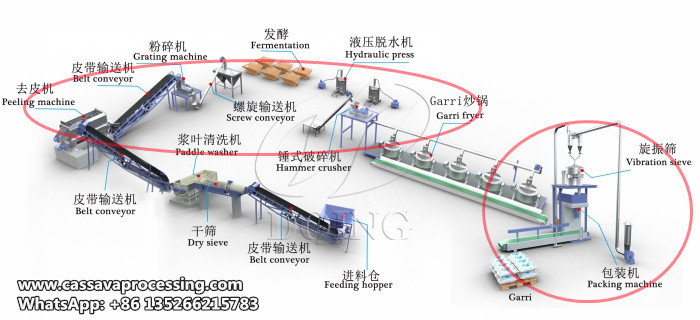

Garri processing is divided into two stages, the cleaning section and the processing section.

Cleaning section

Cleaning section of garri processing machine including dry sieve, paddle washer, and peeling machine.

First:Put the fresh cassava root into the feeding hopper, and then transported it to the dry sieve by the belt conveyor.

Then:Through the continuous rotation of the dry sieve, impurities such as cassava leaves, weeds, and stones are screened out.

Garri processing cleaning section

Garri processing cleaning section

Next:Through the principle of countercurrent cleaning, the paddle washer uses continuous flowing water to clean the soil on the cassava and reduce impurities in post-processing.

Afterward,the cassava will go into the peeling machine. The peeling machine adopts the sand roller design. By adjusting the speed of the propulsion screw, the friction time of cassava tubers on the emery roller can be changed to achieve a peeling effect of about 96%.

Processing section

Processing section in garri including grating machine, hydraulic dewater, garri fryer, and vibration sieve.

The cleaned and peeled cassava is crushed into the mud by a grating machine and then transported to the distribution bin by a screw conveyor after bagging.

Workers transport it to fermentation racks to ferment for 2-3 days to produce the unique flavor of garri.

The fermented cassava puree will be dehydrated in a hydraulic dewater. Workers only need to put the cassava mash into the drum, and then press the jam through the hydraulic dewater.

Garri processing section

Garri processing section

The pressed cassava mash will be transported by the screw conveyor to the hammer crusher and broken into small pieces, which is convenient to save subsequent frying time.

Afterward, through a stainless steel garri fryer, the cassava is constantly stirred, fried, and finally turned into the finished garri. The garri fryer can realize automatic stirring, and workers can control the operation of the equipment through buttons and handles.

The processed garri will pass through the vibration sieve to screen out more uniform fruit particles to obtain high-quality products.

Finally, use a semi-automatic packaging machine to pack the produced garri into 25kg-50kg/bag for storage.

This is the whole process from cassava to garri. If you have plans to start a garri processing business, please feel free to contact us.

Leave a message about How garri is processed from cassava?

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others