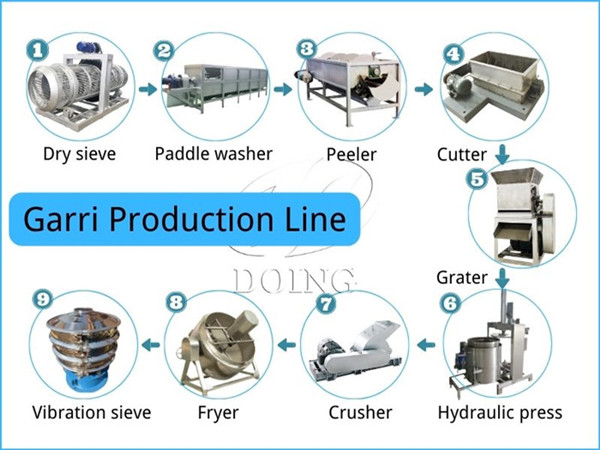

Garri production equipment

Date:

Date:

December 22, 2022

- WhatsApp:

- Tel:

- Phone:

- Email:

The function of garri production equipment is to process cassava into garri, which mainly includes washing equipment, grating equipment, de-watering equipment, frying equipment, crushing equipment, sieving equipment, and packing equipment.

Washing equipment: Involves dry sieve and paddler washer. A dry sieve is mainly to remove large particles on the surface of cassava. A paddle washer is a garri production equipment designed according to the customer's requirements, a single-slot washer is suitable for small capacity garri processing, while large capacity can adopt double slots to increase production capacity.

Peeling equipment: Using a sand roller design to remove cassava peels, this garri production equipment is mainly to ease the cassava grater's burden and gain higher quality garri. This cassava peeling equipment peeling rate can reach 96%.

Cassava peeler

Cassava peeler

Grating equipment: It is mainly used to crush cassava to wet mash for convenience in fermentation. A high speed cassava grating equipment can distinguish cassava cells fully and improve garri yield.

Fermenting: Fermenting is necessary for garri processing but does not require garri production equipment. Just pile the packaged cassava pulp into a room to let them fermentate for 2-3 days. Fermentation mainly changes the taste of garri to make it satisfy human needs.

De-watering equipment: A hydraulic press machine is for garri dewatering, it can dewater the fermented wet cassava to 38%-40%. It is easy to use, just pull out the inner chamber, put in the fermented garri, and the device will dewater automatically.

Crushing equipment: The hammer crusher is used to break the dewatered cassava wet cake into small pieces, which is save the time of frying garri and is convenient for subsequent frying.

Garri frying machine

Garri frying machine

Frying equipment: Garri frying (click to see the video) is a process of dry garri into edible dry white and yellow garri. Meanwhile, the fried garri can be stored longer.

Technical parameters of garri fryer:

| Model | Diameter(mm) | Depth(mm) | Stirring power(kw) | Capacity(kg/h) |

| DYC-300 | 1000 | 390 | 1.5 | 40 |

| DYC-400 | 1000 | 420 | 1.5 | 60 |

| DYC-500 | 1000 | 450 | 1.5 | 100 |

| DYC-600 | 1000 | 450 | 3 | 150 |

Sieving equipment: If you want to make high quality garri and sell it, it is necessary to screen the fried garri into smaller sizes, in this way it will be worth more money.

Packaging equipment: Of course, this garri production equipment is also suitable for garri that is ready to sell. It has different scales for you to choose.

Leave a message about Garri production equipment

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour