How to select a fully integrated system to produce cassava flour and starch

As the largest cassava-growing country in Africa, in recent years, with the changes in social needs, people are no longer satisfied with selling fresh cassava, but to increase the commercial value of cassava, cassava flour and cassava starch have become people's choices.

In the process of exploring the processing of cassava, many people have great doubts about whether it is possible to produce cassava flour and starch at the same time on one production line. Here we will introduce it to you.

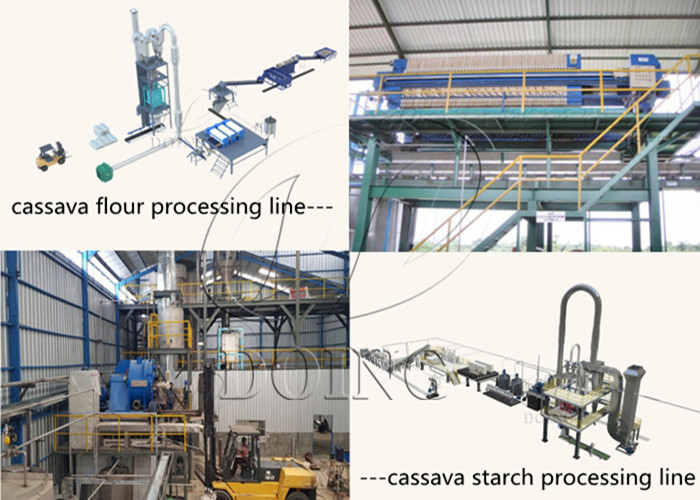

Cassava flour and starch processing lines

Cassava flour and starch processing lines

Normally, cassava flour and cassava starch are different processing lines. Cassava flour processing includes washing, peeling, grinding, dewatering, and drying.

Cassava starch processing includes washing, grinding, separating, refining, dewatering, drying, and sieving.

Cassava washing and cleaning machines

Cassava washing and cleaning machines

Compared with cassava flour production, cassava starch production requires higher processing technology and more machines, which means that purchasing a cassava starch processing machine requires a higher budget. Many customers want to produce tapioca flour and tapioca starch at the same time with a limited budget, Jinrui can provide customers with effective advice. In the washing part, all cassava processing lines use the same machines including a dry sieve and paddle washing machine. So if you want an integrated system for the two cassava production projects, Jinrui can provide the same cassava washing and cleaning machines, then design the later processing machines for you.

If you want to start an integrated cassava flour and starch project, welcome to consult us for more details. Henan Jinrui will give professional plans.

PREV:How lucrative is cassava processing business in Nigeria?

NEXT:How to dry sweet potato starch, machine drying or manual drying?

Leave a message about How to select a fully integrated system to produce cassava flour and starch

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others