Vibration sieve

Date:

Date:

April 28, 2018

- WhatsApp:

- Tel:

- Phone:

- Email:

Vibration sieve is designed as a high-precision screening machinery. It is composed of vertical motor, and eccentric weight installed at two ends. The purpose of vibration sieve is dry classification -separation of solid particles into precise sized fractions. It is widely used in garri and cassava flour sieving process.

The principles of the vibration sieve:

Two vibration motors installed on the equipment which work in simultaneously and reverse rotation. The screen box supported by the four springs produce reciprocating linear motion under the vibration force generated by the motors. When the vertical component of the vibration acceleration is greater than acceleration due to gravity g, material in the tank was thrown up, press forward to jump along parabolic path. Each vibration of the tank, the material would be thrown up once. In the process of encounter with the screen, the material which is smaller than screen mesh can go through it, so as to achieve classification purpose.

Vibration sieve

Main Features of the vibration sieve:

1.Stainless steel wire woven net is easy to clean and operate.

2.Completely enclosed structure is adopted so the particulate matter pollution in the air is quite limited.

3.The energy consumption of our flour vibrating sieve machine is small; Low noise; Attractive and durable.

4.Able to separate different materials including granules, powder, liquid, salt, sand, chemicals.

5.Mesh size can be designed from 5-500 mesh; Small in size and easy to move, convenient for install and clean.

6.The outlet hole can be adjusted 360 degrees, easy for separation.

7.Easy to change mesh, which just only need 3-5 minutes because of the unique screen.

8.Can be designed with different layers according to your materials; Good quality vibrating motor to improve separating efficiency and save energy.

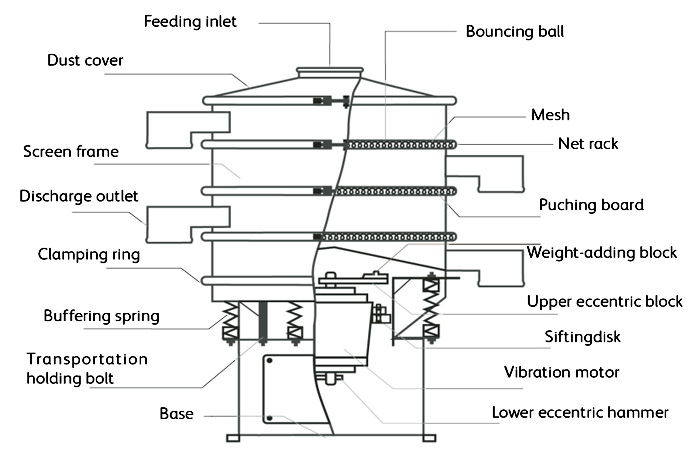

Vibration sieve structure

Doing Company vibration sieve technical parameters:

|

Model |

DYS-500 | DYS-600 | DYS-800 | DYS-1000 | DYS-1200 | DYS-1500 | DYS-1800 | DYS-2000 |

|

Diameter (mm) |

500 | 600 | 800 | 1000 | 1200 | 1500 | 1800 | 2000 |

|

Screen diameter (mm) |

430 | 530 | 730 | 900 | 1100 | 1400 | 1700 | 1900 |

| Layer | 1-5 | |||||||

| Mesh | 2-500 | |||||||

| RPM | 1460 | |||||||

| Feeding size(mm) | <20 | <20 | <30 | <30 | <50 | <50 | <50 | <50 |

|

Power (kw) |

0.25 | 0.25 | 0.55 | 0.75 | 1.1 | 1.5 | 2.0 | 3.0 |

About our vibration sieve, you can decided in the light of your capacity requests. Accept customized:

Voltage: 110V-550V, single phase/three phase, 50HZ/60HZ

Material: Full stainless steel, or carbon steel with contact part stainless steel

Sieve layers quantity: 1-5 layers

Sieve diameter size: 450mm--2000mm

Sieve mesh: 2-500 mesh/inch

Main Benefits of the vibration sieve:

Vibration sieve parts

1.Improve your product purity - Eliminate oversized material from your powders and liquids

2.Increase your production - These vibratory screeners achieve a higher throughput per unit mesh area compared to conventional vibrating screens

3.Reduce your down-time - Can be easily stripped down and cleaned without tools

4.Eliminate dust and fumes - Enclosed screening means total containment

5.Fits into smaller spaces - These vibrating screens can fit easily into existing installations and areas of limited headroom

6.Lowers noise levels - A solid rubber suspension gives the machine a quiet operation

Vibration sieve under package

Application Industries of the vibration sieve:

Chemical industry: resin, paint, industrial drugs, cosmetics, paint, Chinese medicine powder.

Food industry: sugar powder, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice and so on.

Metal, metallurgical and mining: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide,

Electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin ,lime, alumina, heavy calcium carbonate, quartz sand and so on.

Pollution treatment: waste oil, waste water, dyeing and finishing wastewater, additives, activated carbon and so on.

To sum up, vibration sieve is high screening efficiency. The screen mesh of vibration sieve can be made full use of. It can be equipped with screen cloth cleaning device, which can effectively avoid clogging. Small volume, move easily. Vibration sieve adopts whole sealing structure design. Convenience of installation and service. Horizontal distance between inlet port and outlet port is small, which make the arrangement of machines easier. Direction of outlet port can be changed within 360 degrees.

PREV:Cassava crusher

Leave a message about Vibration sieve

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour