Cassava crusher

Date:

Date:

May 15, 2018

- WhatsApp:

- Tel:

- Phone:

- Email:

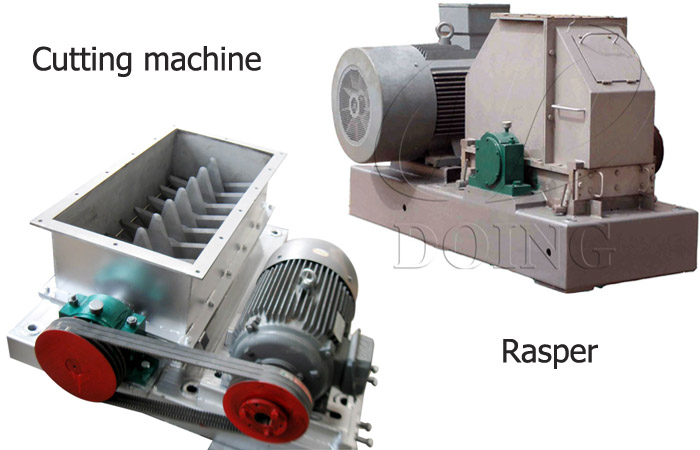

Cassava crusher plays a key part in the whole process of cassava starch processing line or cassava flour processing line. In the production line, the machine can crush cassava into a kind of mush. Then the dryer machine dry cassava mush, the cassava mush will become cassava starch or cassava flour. Cassava crusher can be divided into two kinds of machines, which are cassava rasper and hammer crusher. The following part will introduce the details of the two machines.

Cassava rasper

(1). Cassava rasper is one of the cassava crusher. It is widely used in starch processing industry for crushing materials. It has features of modern design, compact structure, high speed, high rasping coefficient and high extraction rate. Cassava rasper is one of achievements of Doing company cooperate with the international advanced technology. Besides, the machine has a lot of advantages. The rasper part use the modular design, so it is easy to change. The touch part is stainless material, the machine can accords with the hygienic requirements.

Rasper technical parameters:

| Model | CM-250 | CM-300 | CM-350 | CM-500 | CM-600 |

| Rotor width(mm) | 250 | 300 | 350 | 500 | 600 |

| Power(kw) | 7.5-15 | 55-90 | 110-132 | 160-200 | 200-250 |

| Weight(kg) | 1500 | 2700 | 3200 | 3800 | 4500 |

| Capacity(t/h) | ≤6 | ≤12 | ≤20 | ≤30 | 40 |

The working principle of cassava rasper : The cassava to be processed passes through a conveyer from the cleaning machine into cassava rasper. The conveyer can steadily feed the cassava onto the high-speed rotary rasper crushing rotor. Due to the centrifugal force, the saw blade and clamping device are thrown to the outer edge. Thus, the peak of the saw blade teeth protrudes on the surface of the grinding rotor. The cassava are mashed with files and sharp teeth. Grated cassava paste arrives on the sieve, which prevents unground cassava from being removed from the machine. Under such processing conditions, cassava can fully release starch.

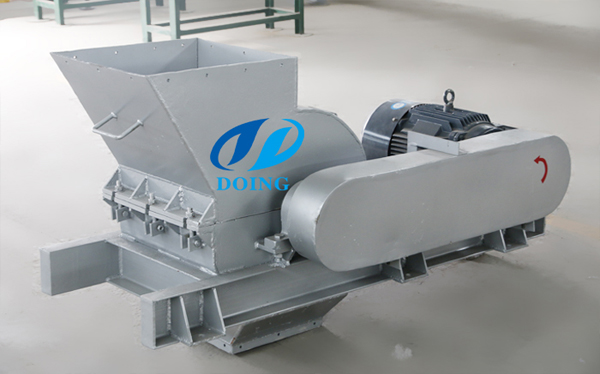

(2).The other cassava crusher is hammer crusher. The machine is widely used for crushing potato, sweet potato and cassava. Therefore, it can be used in the starch processing line and cassava flour processing line and so on. The machine consumes low energy and has high capacity. The machine has simple structure, so it is easy to maintain.

The working principle of hammer crusher: After entering this kind of cassava crusher from the feed mouth, the cassava block was repeatedly hit by the punching plate and the tooth plate collided. The cassava block was broken into the shape of a pellet, and then fell into the hammer crusher through a screen net for fine crushing.

(3). The comparison of the two cassava crushers

Cassava rasper is more situable to starch processing line, because the machine has a high crushing rate, high rasping coefficiency. Usually, cassava rasper can guarantee a high extraction rate of cassava starch, so it can contribute to the production of high-quality cassava starch.

While hammer crusher is mainly used to garri processing line and cassava flour processing line. Because the machine has not high rasping coefficiency as cassava rasper. But the machine also can break the raw material strongly.

The two kinds of cassava crusher both consume low energy, and deal with large amounts of cassava. The two machines are both made by Doing company. Doing company not only provides high-quality cassava crusher, but also produce the whole cassava starch processing machines and cassava flour processing machines.

NEXT:Vibration sieve

Leave a message about Cassava crusher

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour