Cassava flour production process for cassava processing

Date:

Date:

June 13, 2019

- WhatsApp:

- Tel:

- Phone:

- Email:

Casava flour production process is a physical process, for there is no chemical changes happens in the whole process. In cassava flour production process, the starch is firstly released from cassava through physical grating, then starch is extracted from grated cassava pulp that contains a lot of soluable and insoluble impurities, finally the pure starch is dried to market standards.

Cassava flour production process

Cassava flour production process

Here, I will introduce you every steps of cassava flour production process:

Sorting and weighing section: Before processing, we need to choose high quality cassava for cassava flour production process, these intact with no damage will be better. Then we need to weight them and pail them on the ground.

Cassava cleaning and washing section: In cassava flour production process, weighed cassava should be cleaned to remove the attached impurities. If the cassava comes from sandy land, a dry sieve can clean it well. While if the cassava comes from clay land, our engineer can design a spray system at the end of the dry sieve to achieve a beeter cleaning effect. After clean, the cassava still have small dirts and soil, therefore we use a paddle washer to wash off these impurities.

Cassava grater

Cassava grater

Cassava grating section: There are two ways for cassava grating in cassava flour production process. Firstly, we can peel cassava first and then grate it. This method is fit for hammer crusher type grater. For peel cassava can ease the burden of grater and improve the grating rate. But now with a rasper, we can omit the peeling stage. For rasper can rotate with a high speed to fully break cassava cell and extract starch. Rasper is high in price due to its high efficiency, so you can choose one of them based on your budgets and demand.

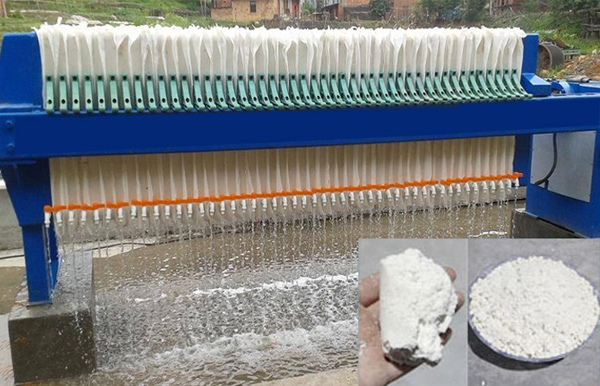

Dewatering section: Dewatering happens in a plate frame filter press machine, where its moisture content is mechanically reduced to about 40%. 40% is a most fitable moisture for drying, therefore it is important to adjust its dewatering effect before cassava flour production process starts.

Dewatering machine

Dewatering machine

Drying section: In cassava flour production process, drying normally happens in air flow dryer where high speed air mix with wet flour for heat trandsfer. Normally drying process finish in 1-3 seconds, with a capacity of 2-10 t/h.

Milling section: The dried cassava flour sometimes are in block, so a miller can be used at the end of flash dryer to mill cassava flour into power.

Air flow dryer

Air flow dryer

Sieving and Packaging section: For high quality cassava flour processing, sieving is necessary, for it can sieve off lager flour and make sure the left cassava flour finer and more delicate. And the last section in cassava flour production process is to pack cassava flour appropriately.

My company, Henan Doing Mechanical Equipment Co.,Ltd focus on cassava processing equipment import and export business. we are the professional manufcaturer of cassava flour processing line and the other cassava processing machine. We have exported many complete sets cassava flour processing line to Nigeria, Tanzania and other Africa countries. According to clients budget, we can adjust the cassava flour processing equipment list,and do our best to supply clients with most suitable cassava flour production process solution.

Leave a message about Cassava flour production process for cassava processing

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others