Machines used for processing of cassava into flour

Date:

Date:

June 5, 2018

- WhatsApp:

- Tel:

- Phone:

- Email:

Now cassava flour has a promising market in tropical areas, because it is a kind of main food, which is popular among people in tropical areas. For processing of cassava into flour, the most important thing is to guarantee cassava fresh. If cassava are not fresh or have been reserved for a long time, then the quality of cassava can not be achieved.

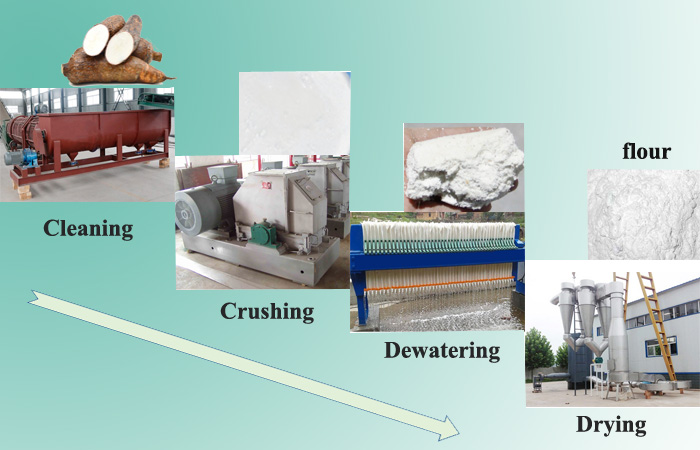

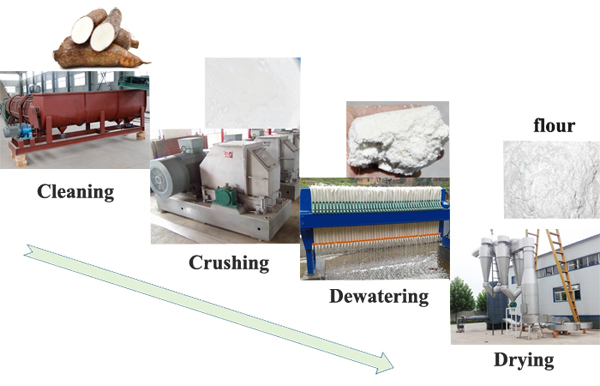

But many people there have to make cassava flour by labor. Then the next will explain what are the machines used for processing of cassava into flour. The whole process mainly include cassava cleaning and washing, cassava peeling, cassava crushing, cassava flour dewatering, cassava flour drying and cassava flour sieving and packing. On the following is the divided introduction:

Cassava flour production process

Step 1. Cassava cleaning and washing

The step mainly includes two machines: cassava cleaning machine and paddle washing machine.

Cassava cleaning machine: it is used to remove outer dirt and impurities of cassava. For processing of cassava into flour, the machine can also help to remove some impurities of cassava.

Paddle washing machine: after cassava cleaning machine, cassava will be transported to paddle washing machine. The machine adopts countercurrent priciple to wash cassava. Cassava will flow in the counter direction against water, then the cassava will washed cleaner.

Doing Company cassava flour processing machine

Step 2. Cassava peeling

Cassava peeling machine: then cassava will be peeled by cassava peeling machine. And the peeling rate is above 95%. Though many cassava flour processing factories do not own this machine, the peeling machine can help to the better quality of cassava flour.

Step 3. Cassava crushing

Cassava rasper: rasper can crush cassava with high extraction rate. rasper has features of modern design, compact structure, high speed and high rasping coefficient. In many factories for processing of cassava into flour, hammer mill will be used, but the machine has lower extraction rate.

Welcome to DOING

Step 4. Cassava flour dewatering

Plate and frame filter press: it is an effective type of dewatering equipment. At this time, cassava mush will be dewatered by the machine. The machine is designed with integration of machines, electricity and liquid, which can realize automatic pressing with high degree of automation. It is an significant step in processing of cassava into flour.

Step 5. Cassava flour drying

Flash dryer: the machine adopts negative pressure and cooling system. The whole drying process is completed in an instant, so the degradation and deterioration of cassava flour do not exist.

Automatic packing machine

Step 6. Cassava flour sieving and packing

Vibration sieve: it is used to sieve cassava flour, then the final product will be finer and be removed some sand and other things.

Automatic packing machine: the finished product will be packed by automatic packing machine. The machine has high effiency and saves labor. The packing step for processing of cassava into flour will be finished in a short time.

All in all, the main machines for processing of cassava into flour mainly include dry sieve, paddle washing machine, cassava peeling machine, rasper, plate and frame filter press, flash dryer, vibration sieve and automatic packing machine.

PREV:Nothing

Leave a message about Machines used for processing of cassava into flour

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour