The process of garri processing line

Date:

Date:

Jun 18, 2019

- WhatsApp:

- Tel:

- Phone:

- Skype:

elina881130

- Email:

In African countries such as Nigeria, garri processing is an important way to process and add value to cassava. Garri processing involves the process of washing, peeling, grinding, fermentation, dehydration and drying.

1. Washing: Washing step is quite simple, which just use water to wash away the dirt, soil and other impurities on cassava. It requires to wash all the debris on cassava, for they may influence the final quality of garri.

Washed cassava

Washed cassava

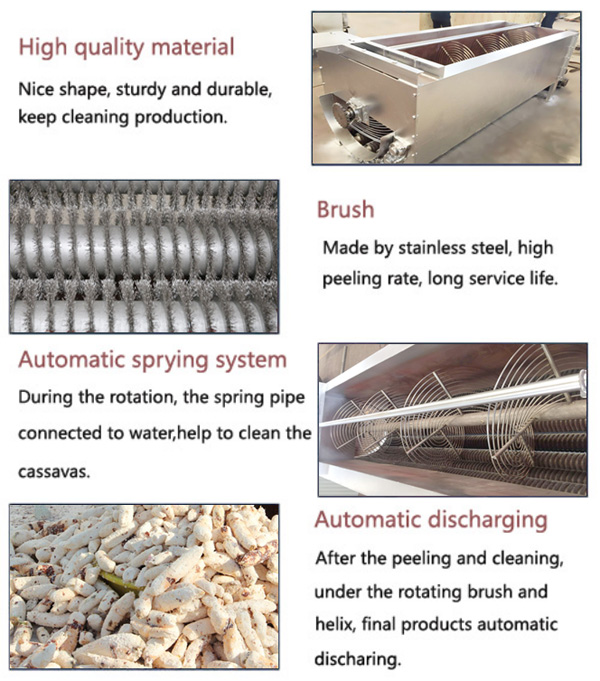

2. Peeling: Peeling is important for garri processing, using a knife to cut off the gray outer peels of cassava. Mechanical peeling adopts cassava peeling machine to automatically peel cassava.Due to cassava has irregular shape, peeling by machine normally can not achieve a 100% peeling rate. DOING cassava peeling machine can reach a peeling rate of more than 95%, which is more efficient than other machine and can basically remove the peels. In this step, the toxic cyanide in the cassava epidermis is basically removed.

Cassava peeling

Cassava peeling

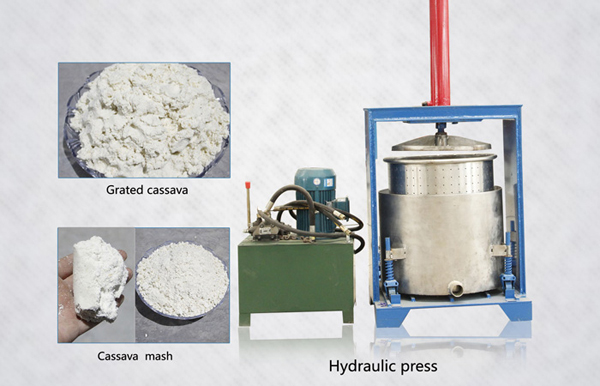

3. Grinding: Grinding is regarded as the most important step for garri processing, it breaking the cassava cell to release all the staff in cassava. The grated cassava is in the state of cassava pulp, then it is packed in bag and stack in a room to ferment for 2 or three days.

4. Fermentation: The fermented cassava pulp requires to be dehydrated to moisture content that easy to be fried. In this step for garri processing, garri is easily be polluted, so it will be better to use a stainless steel machine for dewatering. DOING hydraulic press is designed with corrosion resistant stainless steel material for inner part, ensuring garri quality.

Hydraulic press

Hydraulic press

5. Frying: Frying is to dry the wet garri to an extent that is easy to store, because the hot whether in Africa makes all food easy to rot, therefore this step is also important for garri processing. There are two ways for garri frying. Using a traditional garri wok or automatic garri fryer. Traditional garri wok is fit for family processing. While garri fryer is suitable for garri processing plant, for it has a roller to evenly stir garri, so that the produced garri has uniform water content and high quality.

If the produced garri is for self eating, packaging can be omitted. If the garri is for sale, a packaging machine can be chosed to pack garri, thus the garri can be sold for a better price.

Garri fryer

Garri fryer

Garri processing is vital for African countries, especially with the increase of population, garri and cassava plays important role in food safety. The appearance of high efficient and highly automatic garri processing machine making garri processing can be finished in just 30 minutes, which frees people from the complicated labor. In addition, the new garri processing method also attract more and more young people engaged in garri processing business, for traditional garri processing is dominated by woman and old people. In this way, it can provide youths with more job opportunities, and reducing the poverty in poor countryside area. What's more, garri processing requires low investment and can gain high profit, is a worthwhile investment. Doing Company is a professional garri processing machine manufacturer, we not only has own factory, and our oversea warehouse is under building. Our engineer and sales manager can give you best guide and solution for you based on your requirements. Welcome your visit to our factory and overseas warehouse.