How to make garri from cassava ?

Garri is one of many different kinds of food products that can be produced from fresh cassava roots. garri is dry, crispy, creamy-white and granular. It is made from cassava roots that have been crushed into a mash, fermented and sieved into small pieces (known as grits). In this article, we will see how to make garri from cassava.

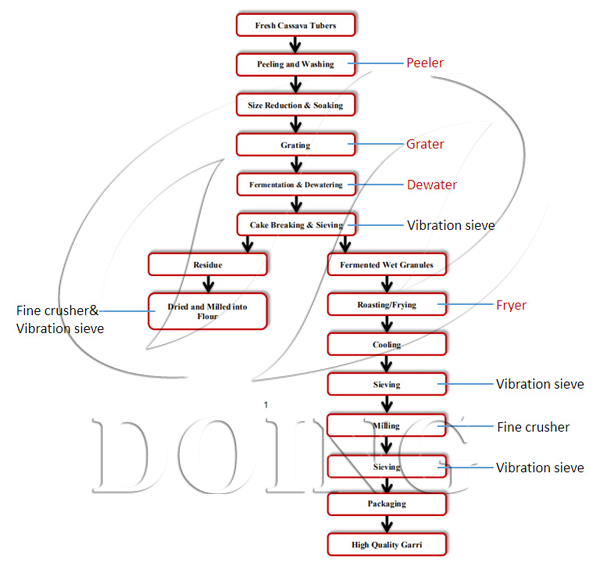

The following flow chart clearly shows the process of how to make garri from cassava:

Here are the detail step for how to make garri from cassava:

Step 1: Washing cassava

Freshly harvested cassava roots are covered with soil and dirt and some may be damaged or rotten. Only healthy roots (without rot or other damage) should be transported to the factory. Because Fresh cassava is easy to go bad, so after cassava harvesting, the better for people to process it earlier.

After harvesting, traditional method to make garri from cassava is washing the peeled tubers. Use a lot of water because this is the only washing you are going to do.

But with modern technology. We prefer to use a cassava paddle washing machine. so that is can make the continuous garri processing line.

Paddle washing machine

Paddle washing machine

Step 2: Peel off the skin of the cassava tubers. Try as much as possible not to peel too deep.

At the factory, the roots are peeled to remove the outer brown skin and inner thick cream layer and washed to remove stains and dirt. The water source should be clean water to make garri from cassava.

Traditional method is selecting fresh cassava roots without rot or damage. Use a sharp knife to peel the roots and remove the skin. Remove any damaged or woody parts from the roots

While modern technology is using a cassava peeling and washing machine to remove the cassava peel, with machine, it will be more effectively and high output.

Peeling machine

Peeling machine

Step 3: Grating cassava into mesh

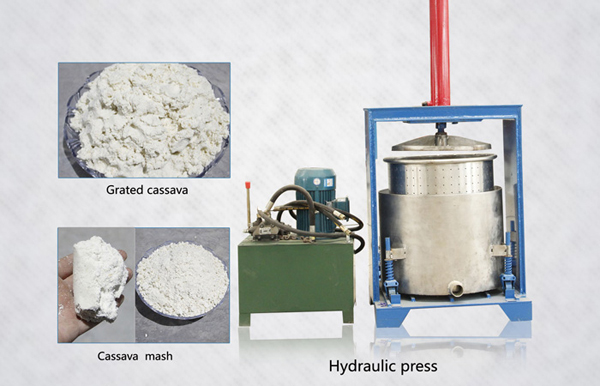

This is the key step for how to make garri from cassava. Cassava roots are traditionally grated into a mash or pulp as part of the process to remove cyanide and make the roots safe to eat. Traditional cassava graters are usually made from perforated metal sheets. these rust quickly and are difficult to keep clean. they are also very slow and labour intensive to use. Mechanized graters are needed to produce a sufficient quantity of cassava mash to meet market demands and standards. Smallholder processors therefore need to learn how to use and maintain these machines.

Garri dewatering machine

Garri dewatering machine

Step 4: Fementation and dewatering

After grinding for processing of cassava into garri, the cassava pulp need to be packed in long bags and drilled to ultimate dryness in a jack for 2-3 days fementation. Then dewatering the cassava pulp into a cassava cake. With moisture around 40%.

Step 5: Sieving and frying

Sieving the wet cake into grits and roasting grits into garri.

Garri is made by sieving the wet cake into small pieces, and then roasting or frying the grits in a hot frying tray or pan to form the initial dry and crispy product. Gari is normally white or cream, but will be yellow when made from yellow cassava roots or when fried with palm oil. It is important to make sure the taste and smell is acceptable to local consumers. Yellow cassava roots and palm oil are rich in vitamin A and therefore make nutritious gari.the product should be free from mould, insects (dead or alive), dirt and any other material that could be hazardous to health.

Garri fryer

Garri fryer

Step 6: Sieving the fried garri

Garri is usually classified by its particle size for processing of cassava into garri: Because different size will decide the price people sell.

Extra-fine: passes through 0.25 mm to 0.5 mm aperture sieve

Fine: passes through 0.5 mm to 1 mm aperture sieve

Coarse: passes through 1 mm to 1.25 mm aperture sieve

Extra coarse: passes through 1.25 mm to 2.0 mm aperture sieve

Garri sieving machine

Garri sieving machine

Step 7: Fine milling

For the coarse and extra coarse garri , normally, we need match another fine mill to milling the garri into better fineness,. which will be high price when we sell it to the market. We call it high quality garri.

Step 8: Packaging

Normally , garri will be packed in small packages, with 100grams to 5000grams. etc

Garri packing machine

Garri packing machine

Some people will add some nutriment or milk etc to make different style of gari tastes, which will make it more valuable. And make more profit.

So, for the above it is what we introduce for you the modern technology of how to make garri from cassava. The grits are then roasted or fried to make the initial crispy product. Garri is a popular food in West Africa and is fast becoming a marketable product. Our company mainly fibricating different machines to process cassava to garri, if you are interested in the garri business, Please welcome to contact us.