How to get high quality potato starch?

Potato starch

75% of the potato crop is grown for industrial potato starch processing and the Danes produce per capita more starch than any other nation.

Occurrence of starch:

Starch constitutes the nutritive reserves of many plants. During the growing season, the green leaves collect energy from the sun. In potatoes this energy is transported as a sugar solution down to the tubers, and it is down there that the sugar is converted to starch in the form of tiny granules occupying most of the cell interior.

The conversion of sugar to starch takes place by means of enzymes. Then next spring, enzymes are also responsible for the re-conversion of starch to sugar - transported upwards as energy for the growing plant.

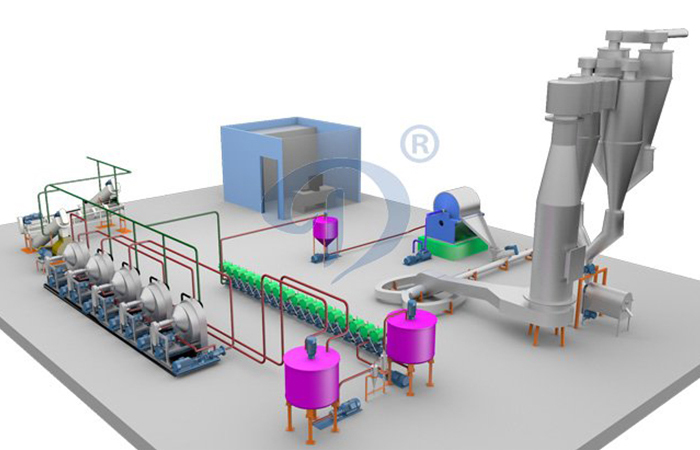

Potato starch processing machine

In order to get high quality potato starch, you need to pay more attention as following before potato starch processing:

The basic for starch quality is laid in the potato clamp:

In the field or stored in clamps during winter, the tubers stay alive and need some air for respiration and life activity.

Potatoes consume a small amount of their own starch during winter to maintain life functions until spring. This requires fresh air and the respiration causes generation of heat.

If the surrounding temperature falls with a risk of frost, the tubers try to save their skin by extensive conversion of starch to sugar in order to lower the freezing point in the cell juice. If this does not suffice, the tubers die. Potatoes therefore must be adequately covered when stored.

If the potatoes get warm, respiration increases, raising the temperature further. A lot of starch is used for the respiration and the tubers will die of heat.

Unfavourable storage conditions cause starch losses and, in the worst case, dead and smashed potatoes, which are disruptive for the process.

Potato starch processing line

Supplies of bad potatoes have to be rejected.

Damage during transport also causes quality problems. Every single blow damages cells, with starch losses and a dead spot on the tuber as a result. It is therefore of utmost importance to handle the potatoes during transport as carefully as possible with the techniques and equipment available.

Refining begins already during raw material intake:

Drop damper for initial filling of empty store.

During unloading at the factory, damage can be reduced by covering buffer silos with rubber and minimising drop impact with rubber curtains. Smashed potatoes loose a lot of juice, causing foam and unnecessary problems in the washing station.

Loose dirt, sand and gravel are removed on a rotating screen before the potatoes are deposited in the store - the better the dirt removal, the lesser the problems with stones and sand in the fluming channels later. The soil also contains considerable quantities of nutrients, which will dissolve in the washing water and contribute to the environmental effect caused by the effluent.

During potato starch processing, the potato store is a necessity to secure the supply of potatoes overnight. Supplies for the weekend may also be required because of restrictions on heavy road transport outside ordinary working hours.

The ideal situation is to reach the bottom of the potato store every morning, because the potatoes suffer during long storage in thick layers without adequate ventilation.