What is the feature of cassava peeling machine for cassava plant?

Cassava has become one of the prominent crops that are required to be provided for both local consumption and export promotion. In 2004, a policy was initiated by the federal government of Nigeria to produce bread with cassava and wheat flour in the ratio of 1:9 in Nigerian bakery industry. Apart from human consumption, cassava is also used for animal feed and alcohol production (Cork J.H 1987).

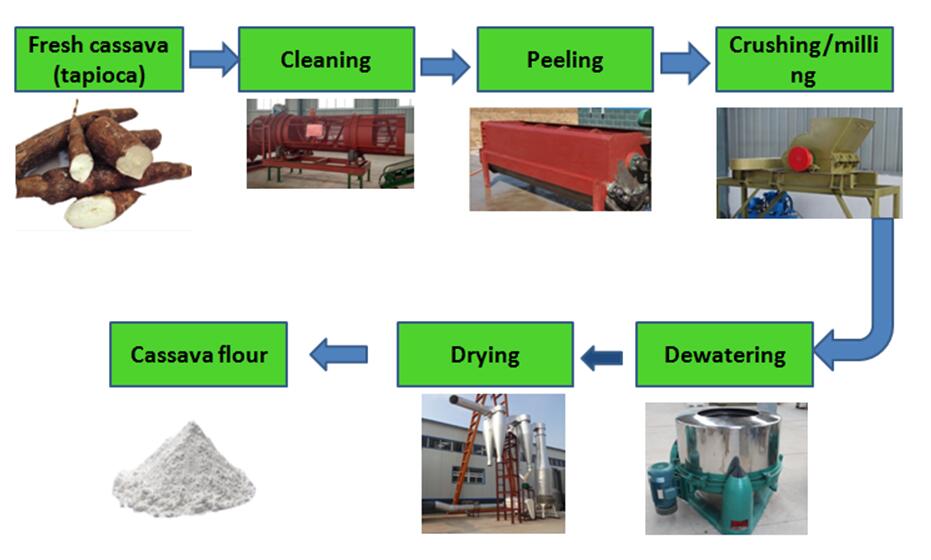

Cassava flour processing machine

There is an ever increasing global demand for cassava chips and pellets, particularly in China and Brazil. Cassava can therefore be referred to as a multipurpose crop for man and livestock. Cassava starch is an ingredient in the manufacture of dyes, drugs, chemicals, carpets and in the coagulation of rubber latex (Odigboh, 1983).

Since 1930, Nigeria has surpassed Brazil as the world’s leading producer of cassava with an estimated annual production of 26 million tons from an estimated area of 1.7 million hectares of land (FAO, 1991). Other major producers of cassava are Congo DR, Thailand, Indonesia, China, India, Malaysia, Malawi, Togo and Tanzania (Odigboh, 1983). Cassava processing thus deserves serious attention in order to meet the local and international demand for cassava products. The unit operations involved in the processing of cassava includes peeling, grating, boiling/parboiling, drying, milling, sieving, extrusion and frying. Several processes for the above mentioned operations have been mechanized successfully, however, cassava peeling remains a serious global challenge to design engineers involved in cassava processing. Research efforts in this area have resulted in the production of several prototypes with relatively low peeling efficiencies and quality performance. This as a result of the different size and irregular shapes of cassava tubers. The size of a cassava tuber depends on the variety and fertility of the soil. The cassava tuber can be divided into three regions. They are:-

I. The periderm: - This is the uttermost layer, which is brown in colour and consists mainly of dead cells, which covers the surface of the tuber.

II. The cortern: - This lies below the periderm. It is usually about 1.5 – 2.5mm thick and white in colour.

III. The central portion of the tuber: - This makes up the greater bulk of the cassava tuber and is composedessentially of stored starch.

Cassava peeling machine

In cassava peeling operation both the periderm and the cortern are removed as waste, and the central portion of the tuber left as the desired output.

There are several methods of peeling cassava, which have been adopted. They include manual, chemical, steaming and mechanical methods. Each has its own advantages and disadvantages.

Manual Method

The manual method of peeling cassava is primitive and cumbersome. It is carried out by hand peeling of cassava using sharp edged object like the knife.

Chemical Method

Chemical method is often adopted in the industries, factories and food processing companies. It involves chemical actions and thermal shock, which leads to softening and loosening of the skin using caustic soda (NaOH). The disadvantages of this method of peeling cassava include:

a. Cost of acquiring caustic soda.

b. The difficulty in controlling the penetration of chemical into the cassava tuber.

c. The difficulty in the removal of chemical traces as it may be poisonous.

Steaming Method

The tubers are subjected to high steam pressure over a short period of time to avoid partial cooking (or eventual cooking). The disadvantage is that the tubers could be subjected beyond the time required, which will lead to cooking.

Mechanical Method

This includes mechanized means of peeling, aimed at peeling a large number or a batch at a time. Many mechanisms have been devised for this purpose. This includes the continuous process, abrasive belt conveyors and batch abrasion types among others.

Our company experts have researched and developed the cassava peeling machine for cassava plant, see the image below:

Cassava peeling machine

Usage of cassava peeling machine for cassava plant:

This cassava peeler machine is designed by brush principle. Cassava peeler is mainly used to peel the cassava root during cassava starch processing, cassava flour processing, as well as garri processing. Cassava peeler can save human work for peeling the cassava. Cassava peeler could also widely used in round oval fruits and vegetables such as cassava, ginger, carrots, potatoes, sweet potato and kiwi fruit, vegetable root tuber crops as cleaning and peeling.

Feature of cassava peeling machine for cassava plant:

1.The cassava peeler machine has beautiful appearance and convenient operation, cleaning peeling of large volume, high efficiency, little energy consumption, clean, simple operation, long service life, etc.

2. The cassava peeler machine can be made of carbon steel material and high quality stainless steel 304 material according to customers’ requirements.

Then if youm are interested in our cassava peeling machine for cassava plant or other cassava machine,weclome to contact us. And our engineer will give you a professional and feasibility program about the cassava peeling machine for cassava plant.