How garri processing machine works?

1.cassava

Cassava is God’s gift to the tropics because it can grow in poor soil with inadequate rainfall. The starchy roots of cassava are major source of food for more than 500 million people all over the world.

Nigeriais the world largest producer of cassava. We produce over 41 million metric tones per annum and we are followed byBrazil,Thailand,Zaire(now Democratic Republic of Congo) andIndonesia.Thailanddoes the largest global business in cassava because it is not part of their food security. They export over $20 billion worth of cassava products annually.Nigeriais embarking on massive expansion of cassava through the Composite Flour Initiative to attain 40 percent Cassava Flour inclusion in all bread. Cassava is produced all over the country but more abundantly in all Southern and Middle Belt States ofNigeriaand is widely consumed as garri and fufu.

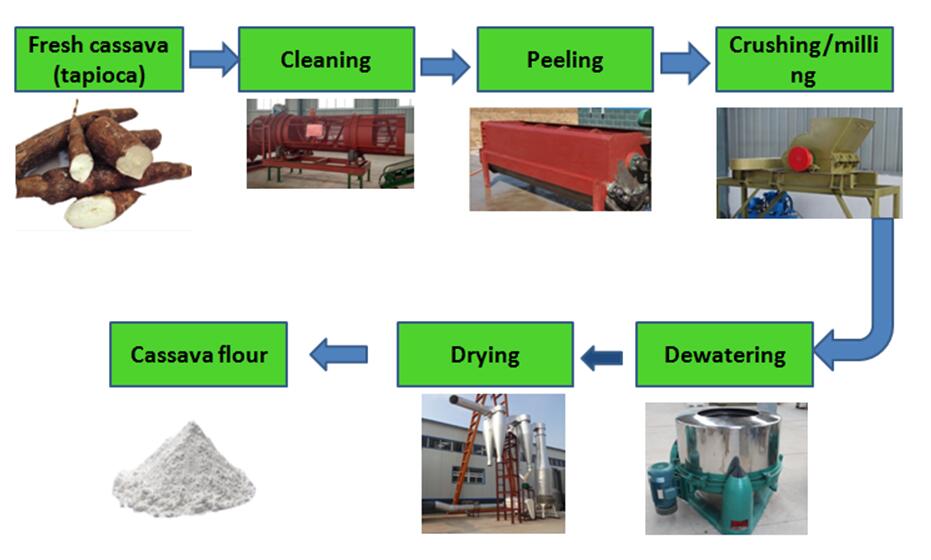

Cassava flour machine

2.garri

Garri is produced from cassava tubers and is the commonest stable food inNigeriaconsumed by over 130 million people. We consume about 7.7 million metric tons of garri per year and it comes to about 30.7 million tons of our cassava production. Our actual demand for garri is 12 millions tons but we can not accomplish that because of the stress and drudgery involved in the traditional production.

Garri is produced in the rural areas (where cassava is grown) by the local women. The young people are not interested because of the stress and the drudgery involved in the traditional production, they will rather migrate to the overcrowded cities where poverty is rampant.

3. Modern garri processing machine

The modern garri processing machine will eliminate the stress and drudgery occasioned by the sedentary nature of traditional garri production. It will reverse the trend of migration to the city and make the youths interested in garri production. It will create local livelihood opportunities that will enable businesses and households to thrive in their local domains rather than be forced to migrate to overcrowded cities where unemployment and crime hold sway. It will create jobs and generate sustainable prosperity to reduce poverty in the rural areas. Modern garri processing using the local cassava will build a local human resource base in the impact areas; this will inevitably lead to empowerment which is the surest guarantee of sustainable growth.

Modern garri processing machine is a sustainable intervention in poverty alleviation because of the abundant availability of the cassava tubers and the huge size of the garri market. It will enable the rural folks to escape extreme poverty and ascend the ladder of economic growth. The garri project will strengthen farm-to-market linkages: Cassava from the farms are processed in the modern processing plants and marketed domestically, regionally and internationally. The market dynamics will create a regional economic engine that will enhance the business objectives.

Cassava cleaning machine

How garri processing machine works?

1. Paddle type cassava washing machine

a. rotating by paddles

b. full of water

c. Small defects are cleaning up

d. Material to the next stage automatically

2. Cassava peeler

a. peeling

b. washing

c. do not hurt the material

d. material to the next stage automatically

3. Cassava grinder

a. two ways of crushing

b. Several national patents owned

c. Low energy and high efficiency with fully automatic

4. Cassava dewatering:

By using the principle of hydraulic and self-weight, nofilter chamber cavity, will directly press and squeeze the water under putting the material into the filter bag to further reduce the moisture content.

5. Garri fryer

a. Double layers with “+’ type mixer

b. Speed automatically controlled

c. Multi heat resources can be selected

d. 24 hours continuous work available.

PREV:How to start a cassava starch processing plant?

NEXT:What is the feature of cassava starch processing machine?