Tapioca starch making machine

Date:

Date:

Jun 11, 2019

- WhatsApp:

- Tel:

- Phone:

- Skype:

elina881130

- Email:

With more requirement of tapioca starch, more and more people start to buy the tapioca starch making machine and produce starch. One of the main reason is that fresh cassava easy to go bad after harvesting from land, so the easiest method is processing them into different products like starch, flour, gari, chips etc, which will make cassava storage longer. But how much do you know about tapioca starch and tapioca starch making machine? Let me tell you more!

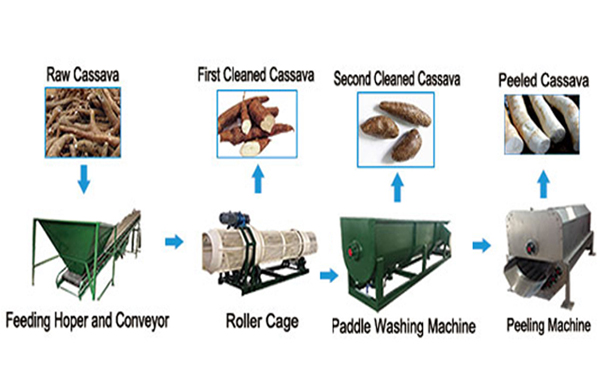

Tapioca starch making machine flow chart

Tapioca starch making machine flow chart

Mainly used tapioca starch making machine can be devided into three section:

Section 1: fresh tapioca cleaning section

Fresh cassava or tapioca will be weighed and then loaded into the hopper before processing.Then with the viberating device of hopper, the fresh tapioca will be conveyed to the dry sieve. Dry sieve is the first tapioca starch making machine used, which mainly use to remove the sand, dirt,stones, impurities and the first layer of peel. But normally, it will remove around 40% peel. Then it is the paddle washing machine, we normally match the double shaft paddle washer, which will ensure more peels will be removed and cassava cleaned completely.

Tapioca starch making machine workshop

Tapioca starch making machine workshop

Section 2: tapioca starch making section

Then, The cleaned roots coming from the root washing section are fed into the cutting machine. The cutting machine will cut the cassava/tapioca into 3~5cm pieces which fall into the rasping-hopper and then they are dosed and distributed to the rasper.

Starch extraction: The cassava pulp will be pumped directly to centrifugal sieve for tapioca starch extraction and then a fine fiber sieving machine to get pure tapioca starch milk. With a desanding machine to remove the sand and muti-stages hydrocyclone groups to separate the protein and purifying and concentration. After these tapioca starch making machine, what we get is pure starch milk with a higher density.

For the tapioca starch dewatering, what we match is peeler centrifuge, which professionally used in tapioca starch industry and ensure a lower moisture of wet starch.

Flash dryer

Section 3: Tapioca starch drying section

After dewatering of the starch milk, the starch cake is transported by belt conveyors to the tapioca starch making machine for drying. Our flash dryer can dry the starch in less than 2 seconds, the speed can be more than 20m/s. After flash drying, the refine starch is transported into a starch silo, where the starch is cooled by retention time. From the silo the starch is extracted by the semi-automatic bagging installation, where the starch is bagged into 25kg bags.