Tapioca flour production machine

Date:

Date:

Jun 13, 2019

- WhatsApp:

- Tel:

- Phone:

- Skype:

elina881130

- Email:

Description of tapioca flour production machine:

Tapioca flour prodution machine

Tapioca flour prodution machine

1.Sorting and Cleaning: The tubers are sorted to select the wholesome roots for production. And then it is cleaned in dry sieve to remove sand, weed and other impurities.

Cassava washing machine

Cassava washing machine

2.Washing: The weighed tapioca roots are then transported into paddle washing machine. And it is washed with sufficient quantity of potable water to remove sand, dirt and other contaminants. 3.Grating: The root is milled to cassava mash by rasper. Rasper is an important tapioca flour production machine for it determines the starch extraction rate.

Cassava grating machine

Cassava grating machine

4.Separating: The fiber is removed from cassava slurry in centrifuge sieve. Then it goes into fine fiber sieve to further separate fine fibers from starch. 5.Concentration and refining: In this process, the widely used tapioca flour production machine is hydrocyclone station. A complete hydrocyclone station can achieve the concentration, recycling and refining of the cassava milk. 6.Dewatering: The moisture content of the mash is reduced mechanically by the vacuum dewater machine to about 38% to prepare for drying operation.

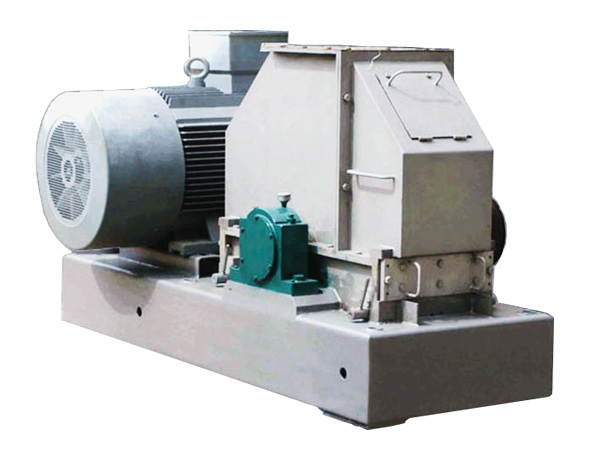

Tapioca flour fryer

Tapioca flour fryer

7.Drying: Dewatering process is followed by drying operation to produce cassava flour of desired quality. Flash dryer is the widely used tapioca flour production machine for drying.

8.Packaging: The tapioca flour is packed by automatic packing machine for storage.

My company can provide you the complete set tapioca flour production machine according to your demand, And we have our own factory and the professional engineers team to provide you with professional guide.