Tapioca flour processing plant

Date:

Date:

August 9, 2018

- WhatsApp:

- Tel:

- Phone:

- Email:

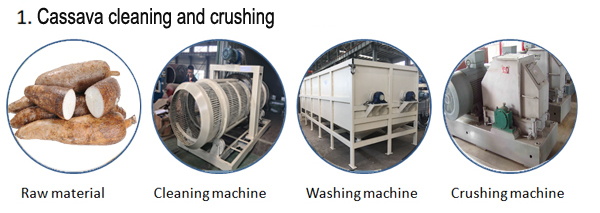

Section 1: cassava cleaning and washing of tapioca flour processing plant

Dry sieve and paddle washing machine will be used in the section. The purpose of cleaning is to remove sand, soil, peel, reduce starch ash, also facilitate the next process. Cleaning at the same time while conveying, so cassava feed must be uniform. If too many cassava are in the paddle washing machine, there is no space, cassava can not roll, which can not achieve the purpose of peeling and cleaning. Too little is not up to production.

Cassava cleaning and crushing machine

Section 2: cassava cutting

Cassava cutting machine will be used tapioca flour processing plant. The tapioca is too long. If cassava can not be cut into pieces, then the next tapioca raser will bear heavy load, the service life of rasper will be shorten.

Section 3: cassava crushing

After cassava cutting, then tapioca will be crushed by tapioca rasper. In tapioca flour processing plant, rasper can crush cassava with high efficiency. And the rasper has modern design, compact structure, high speed, high rasping coefficient and high extraction rate. In tapioca flour processing plant, cassava rasper is a key part.

Tapioca flour extraction process

Section 4: tapioca flour extraction

In the part of tapioca flour processing plant, centrifuge sieve, fine fiber sieve, disc separator and hydrocyclone will be used. First, centrifuge sieve and fine fiber sieve will separate some fiber, impurities and other things. Next, disc separator will be used for removing protein and cell liquid out of tapioca flour slurry. The machine can also concentrate and purify tapioca flour slurry. Finally, Hydrocyclone station is used to remove fiber, protein and cell sap out tapioca milk. The system of the machine contains concentrating, recovering and washing which can guarantee a purer tapioca flour milk.

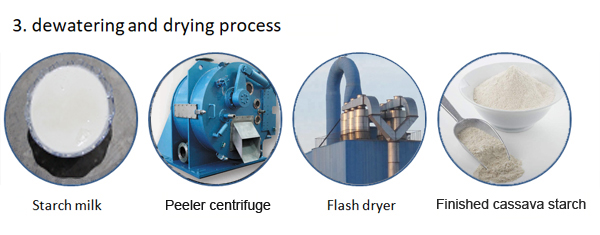

Tapioca flour dewatering and drying

Section 5: tapioca flour dewatering

Peeler centrifuge will be used in this dewatering section in tapioca flour processing plant. The machine adopts continuous operation and intermittent discharging. The machine is an automatic machine which can increase production capacity by 50% and decrease moisture content to 36.5%.

Step 6: tapioca flour drying in tapioca flour processing plant

Flash dryer can dry tapioca flour in a short time. The drying tower adopts positive and negative pressure two-stage drying, the wet air is discharged from the first stage, and the second stage exhausts the air with higher temperature, which is reused into the feed tube. Compared with single stage drying, the energy can be saved 20-40%.

Tapioca flour plant overview

Tapioca flour is obtained from the roots of the tapioca flour processing plant, which is found in equatorial regions between the Tropic of Cancer and the Tropic of Capricorn. The name cassava is generally applied to the roots of the plant, whereas tapioca flour is the name given to starch and other processed products. The large central pith of the cassava roots is the starch-reserve flesh and can range in starch content from as low as 15% to as high as 33%. Anyway, tapioca flour processing plant is used to produce tapioca flour. It is different from cassava flour plant. Tapioca flour is starch, while cassava flour is flour. Cassava must be removed the fiber and protein, then tapioca flour will be extracted from cassava.

PREV:Tapioca flour making machine

NEXT:Nothing

Leave a message about Tapioca flour processing plant

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour