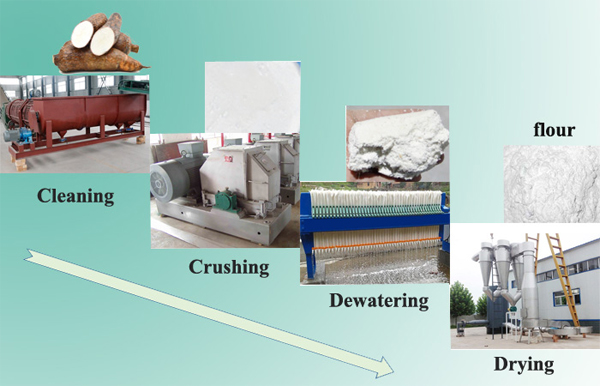

Cassava flour milling process

Date:

Date:

Jun 08, 2018

- WhatsApp:

- Tel:

- Phone:

- Skype:

elina881130

- Email:

In the cassava flour milling process, the purpose of the rasper is to break down the tissue cells of tuber materials subtly. The machine is made of stainless steel, the rotor is forged with special stainless steel, and the rotor is installed with hundreds of specially designed 1.25mm thick two-way composite files. The file in the cassava flour milling process is sandwiched between two conical splint plates, and it is inserted in the conical groove of the rotor to facilitate quick replacement.

The Rasper in the cassava flour milling process integrates the advantages of domestic and foreign products. It has the features of novel design, compact structure and high speed (rotor line speed is about 100 m/s). It depends on the cooperation between Doing Group and international advanced technology.

Rasper

This rasper machine technical parameters:

| Model | CM-250 | CM-300 | CM-350 | CM-500 | CM-600 |

| Rotor width(mm) | 250 | 300 | 350 | 500 | 600 |

| Power(kw) | 7.5-15 | 55-90 | 110-132 | 160-200 | 200-250 |

| Weight(kg) | 1500 | 2700 | 3200 | 3800 | 4500 |

| Capacity(t/h) | ≤6 | ≤12 | ≤20 | ≤30 | 40 |

Structure and principle of the Rasper in the cassava flour milling process:

The machine consists of the machine seat, the machine shell, the rotor, the spindle, the feed inlet, the two-way combination file, the cog belt, the bearing seat, the fixed block, the sieve plate, the motor and the protective cover. Important for the whole cassava flour production. The rotor with the combined file is rotated in the two bearing, the spacing between the fixed block and the file is adjusted by bolts, and the sieve plate is positioned below the fixed block. The independent bearing housing is not contacted with the housing, so it will not be damaged due to the leakage of the file mill. The machine rotates with a file at high speed. The material is screwed into the inter block file and grind into granules, and the uniform emulsion is dropped into the trough through the sieve plate.

The miler in the cassava flour milling process made up for the shortcomings of hammer crusher, It will take a long time to maintain and find a balance point because the hammer and sieve plates of the hammer crusher are rapidly worn away. That is why the Rasper in cassava flour milling processing is indispensable.

Cassava flour production process

Structural features:

1. The processing capacity has been greatly improved to meet the needs of modern cassava flour milling process enterprises;

2. Large diameter of drum, large number of blades and long replacement cycle;

3. Completely broken the cell tissue, small fine fiber, short processing time, long milling path;

4. Special saw blade clamping design for convenient replacement and maintenance of saw blade.

5. Sweden SKF bearing, OPTIBELT cog belt, stable operation and long service life.

Doing Company cassava processing machine

Installation and maintenance:

The precast concrete foundation is prefabricated according to the requirements of the drawings, and the fixed bolt holes are reserved according to the size. The concrete foundation of the mill in the cassava flour milling process must be smooth and horizontal. When the file grinder is installed in the final position, to make sure that the bolt is located in the center of the reserved hole and check whether the machine is completely level. According to the rule, two times pouring concrete slurry in the reserved hole, after that checking the horizontal position again when the concrete slurry is solidified in the hole.