Hydraulic press machine for garri processing line

Date:

Date:

May 15, 2019

- WhatsApp:

- Tel:

- Phone:

- Skype:

elina881130

- Email:

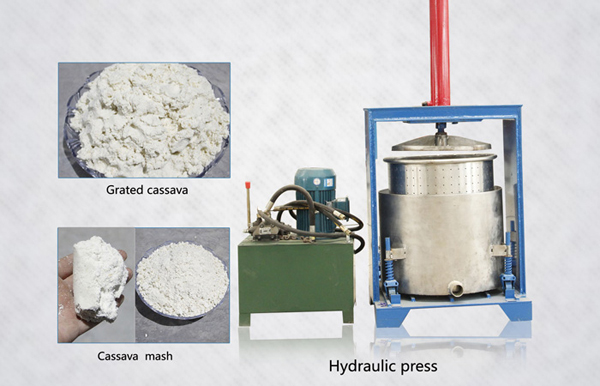

Introduction of hydraulic press machine for garri processing line

The hydraulic press machine is also called as garri dewatering machine. The inner material of hydraulic press machine is food grade 304 stainless steel chamber, which can ensure the clean and hydiene of the dewatered cassava pulp. It is a vital part of the whole garri processing line.

Hydraulic press machine

The principle and structure of hydraulic press machine:

1.Using the hydraulic and self-weight, no-filter chamber cavity, which will directly press and squeeze the starch milk water under putting the cassava pulp into the filter bag to further reduce the moisture content.

2.Two cylinders design; Both in 304 Stainless steel chamber structure

Inside: Use to squeeze the cassava pulp

Outside : Use to collect the starch milk.

Hydraulic press machine

Hydraulic press machine

3.The bucket and the bottom hole design mainly used for collecting the starch milk when pressing the cassava pulp to ensure not any starch milk wasted

In this hydraulic presser process, you can collect 10% pure cassava starch milk;

You will get the cassava cake after dewatering the cassava pulp.The moisture is around 45%.

After the hydraulic presser process, the cassava cake will be fermented for several days and go to next procedure-garri fryer.