How to start cassava flour processing ?

Cassava flour processing plant now own a bright market because cassava flour could be as a replacement for starch. Thai Farm cassava flour has a starch content of about 80% against “pure” starch of only 90%. That is 10% less starch at a price discount of about 30%. Numerous companies are testing our flour as a substitute for starch to take advantage of the cost benefit inherent in using our flour to replace more expensive starch.

Cassava flour processing plant

Its current main application is as a low cost extender for wheat flour produced from imported wheat in the production of: Biscuits, Snack Foods, Bread, Cakes and other baked products. It can also be used for Production of alcohol in beer brewing, Production of glue for use in cardboard manufacture, Production of traditional local foods.

Because of its low protein content, high levels of cassava flour inclusion creates serious challenges in terms of machineability and “lift” and we remain committed to working with our R&D partners to overcome these challenges and grow achievable inclusion levels and so grow savings for our customers during cassava flour processing.

How to start cassava flour processing?

Step 1: Harvesting

Harvest matured cassava from the farm and load it to the processing shed immediately. If the quantity of cassava harvested can not be carried in the same day for logistic reasons do not detach the cassava from the stem and leaf until the vehicle to carry it is ready. That is to say, fermentation will not occur if the cassava is still attached to the leaf and stem even if it has been uprooted. But care must be taken not to bruise the cassava when uprooting it.

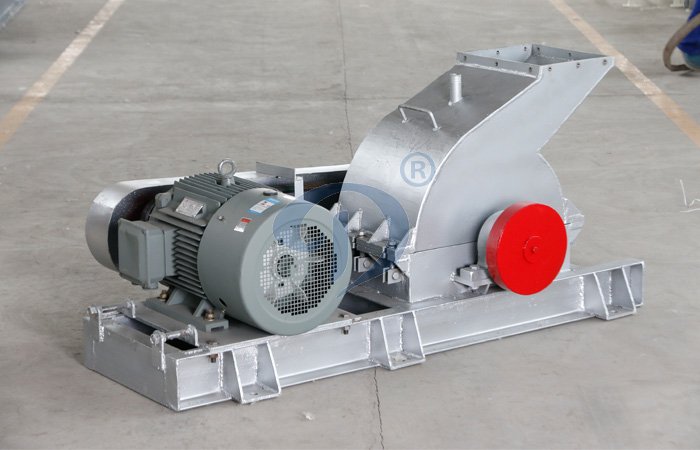

Cassava flour processing machine

Step 2: Washing and peeling cassava

Our cassava peeler could handling large capacity of cassava and well cleaning. This cassava peeler machine is with stable operation and easy maintenance etc. 1. peeling 2. washing 3. do not hurt the material 4. material to the next stage automatically.

Cassava flour processing machine

Step 3: Grinding

The tuber is grinded and become low broken percentage . That means 50% cassava flour is not separated and combined with fiber. In the rasping process, should add process water to dilute slurry. the potato slurry in the collection trough is pumped in to desanding cyclone. Don't make the cassava flour dissociate and make the cassava flour combine with fiber. So the special design of rasper is vital for flour fineness and freeness.

Step 4: Desanding

In the desanding process, sands and sawtooth etc coarse particle will be removed from cassava slurry. This unit is made of ceramic cyclongnetts, sands collection tank, automatic desanding valve and back flush device. back flush avoid cassava flour loss in desanding process. Desanded slurry is sent to dewatering unit.

Step 5: Dewatering

Because there is hydrocyanic acid toxic substance in cassava peels. In this unit, we use filter presser to dewatering and detoxification process.

When slurry reaches to certain liquid position in slurry tank, start to dewater by filter presser. Then transport the material to cassava flour drying procedure by belt conveyor.

Cassava flour processing machine

Step 6: Drying

Dewatered cassava flour cake contains high moisture to 45~50%, which can’t enter into flash dryer directly and will be mixed with dry flour and reduce the moisture to 38%, then transported to feeding port of flash dryer by conveyer belt, pass through feeder and enter into raiser. The heat source of flash dryer is steam heat exchanger. Wet cassava flour is heated by hot wind and water is steamed. After drying, cassava flour and air are separated in cyclone separator. At the bottom of cyclone separator, it is closed by air closer. after wet air leave cyclone separator , which is discharged in to atmosphere. Collected cassava flour is transported to vibration sieve unit; the coarse particulate matter is sieved out. The sieved cassava flour is transported to hopper for storing and cooling.

Step 7: Automatic Packing

1. Automatic weighing and calculating 2. Large adjustable weighing scope from 5-50kg 3. Hand seal, Packing cassava flour in different bags.

Now, if you have any questions about how to start cassava flour processing,weclome to contact us ,and our engineer will give you a professional and feasibility program about the cassava flour processing plant.

PREV:What is the feature of cassava starch processing machine?

NEXT:What are the sales channels of processed cassava starch?