What are the key issues in cassava starch production?

The Nigerian demand for starch has recently been estimated to be around 67,100 tonnes per year. The amount of fresh cassava roots needed to produce that amount of starch is 350,000 tonnes. Out of the five modern large scale cassava starch factories existing in Nigeria, only two are currently in operation. During the Meeting, experience on starch production at Nigeria Starch Mills Ltd (NSM) was showcased. Three key issues were cited was critical in cassava starch production namely:

1.Input: Good quality raw material for cassava starch production .

2.Process: Machines or equipment needed to address issues of input need to be of the required capacity, otherwise the machines would be idle and therefore unproductive.

3.Output-market for starch, hence there is need for good quality input as well as reliable and consistent supply.

It would appear that the above requirements are easy to meet since Nigeria is the “King” for cassava starch production worldwide. However, the challenge has always been that of converting theoretical advantage into practice. Prior to recommending an appropriate scale for starch production in Nigeria, it is necessary to carry out an in-depth analysis on starch production to determine where the comparative advantage lies.

Here is the introduction of cassava starch production:

step 1- sorting: The roots are sorted to select wholesome roots for processing.

step 2- weighing: The sorted roots are weighed.

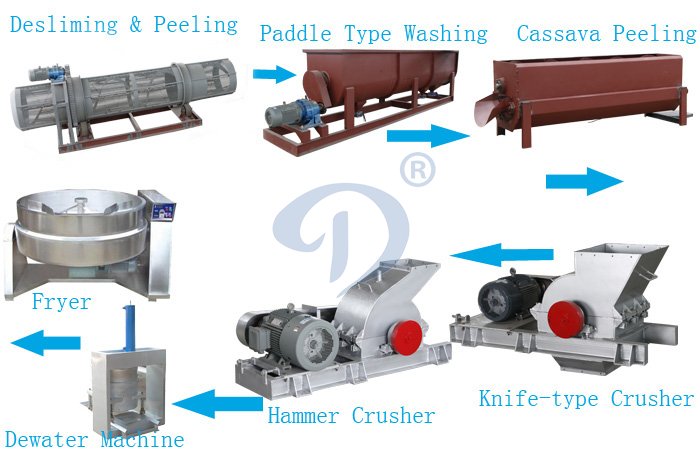

Cassava starch production line

step 3- cassava peeling: The roots are peeled to remove the peels.

step 4- cassava grating: The peeled roots are grated to produce a smooth mash.

step 5- cassava extracting: The mash is discharged into a starch extractor to extract the starch.

step 6- sedimentation: The starch milk is allowed to settle forming two layers i.e. the top free supernatant liquid and the thick starch slurry.

step 7- dewatering: The supernatant layer of liquid is removed by siphoning off the liquid with rubber hose and the thick slurry obtained is dewatered to reduce its moisture content.

step 8- granulating: The “cake” is mechanically reduced in size to produce fine granules of greater surface area.

The granulated cake is mechanically dried in a mechanical dryer to reduce its moisture content to about 8 – 10 per cent.

step 9- milling: The dried product is milled to desired particle size (if necessary).

cassava packing machine

step 10-packaging: The starch is packaged appropriately.

We hope this article may help you in cassava starch production line,if you have any questions,weclome to contact us.PREV:What are cassava chips production process?

NEXT:Could high quality cassava flour be used in Bakery factory?