What should I pay more attention to start a cassava starch processing plant?

There are 3 main things need to pay more attention to start a cassava starch processing plant.

Location of cassava starch processing plant

The factory should be located in an area that is free from environmental pollution and any industrial activities that can pose a serious threat to contaminating food. Areas subject to flooding should be avoided unless sufficient safeguards are provided. The site should be cleared ground from waste, either liquid or solid, can be removed effectively and away from sources of insects and rodents. It should have a good supply of potable water and, if required, electricity. An access road for bringing in raw materials and packaging, and sending out products, is usually essential.

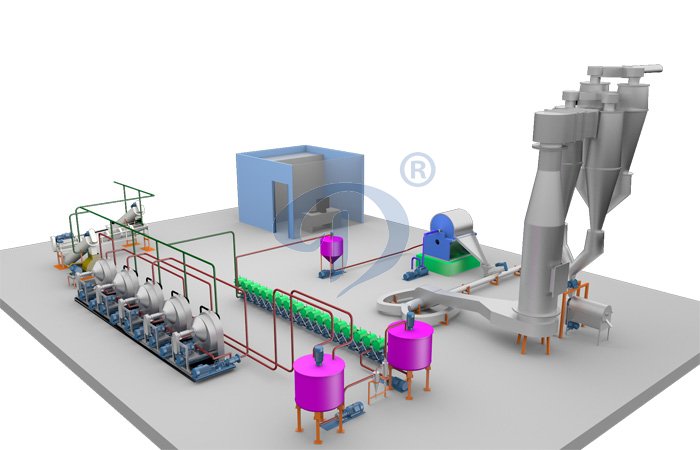

Cassava starch processing machine

The layout of cassava starch processing area

The layout should permit an orderly flow of material through the plant during processing, give enough elbowroom for workers during processing and the cleaning of equipment, and prevent cross-contamination between raw materials and finished products.

Building, structure and condition of cassava starch processing plant

The building to house cassava products may be constructed from concrete or bricks and should provide adequate protection against insects and rodents.

The building should contain a processing hall, an office, a changing room, toilet, ware- housing, and a free lobby.

Cassava starch processing plant

For a medium-scale plant, the factory walls could be built to the window level and completed with expanded metal covered with wire mesh to cut down on costs.

Fixed surfaces of the infrastructure, such as washing troughs and steeping tanks, that come into contact with the processing materials, should have easy-to-clean internal surfaces and be inert to cassava products.

The surface of walls, partitions, and floors should be made of impervious materials with no toxic effect in intended use and have a smooth surface up to a height appropriate to the operation.

The floor should be constructed with concrete or terrazzo (if affordable), have adequate surface drainage and be easy to sweep and wash.

Ceilings and overhead fixtures should be constructed and finished to minimize the build up of dirt and condensation, and the shredding of particles

Leave a message about What should I pay more attention to start a cassava starch processing plant?

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others