Two ways of cassava starch production line working method

As we all know, one kilogram of cassava starch requires 4.4 kilograms of fresh cassava roots at its starch content of 25%. In China, the large-scale cassava starch processing facilities with advanced processing machines and technology have been replacing those primitive and small-scale factories.

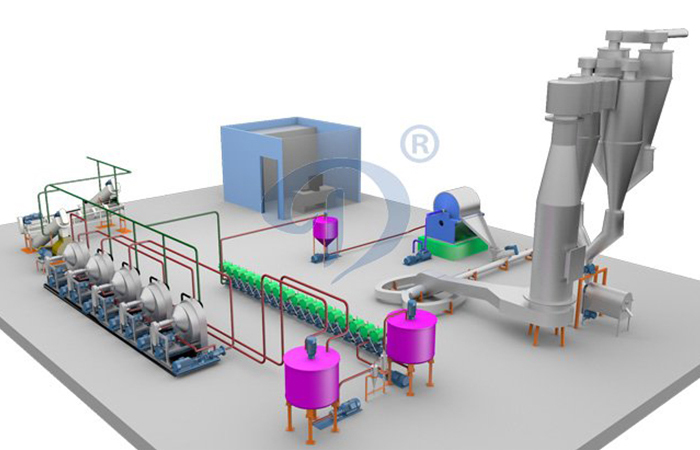

Cassava starch processing line

According to the studies, the cassava starch production line processing methods could be divided into two processes; traditional and modern. Their details are as follows: The traditional process, usually practiced in the small-scale factories, is able to separate starch from fresh cassava roots by crushing and then submerging the cassava under the water. Most starch factories buy cassava roots from growers in their neighborhood, directly or through agents. Some factories, however, own their cassava plantations. Modern processing plants usually contract various growers in the area to supply roots.

The modern process, practiced in the large-and-medium-scale factories relies on numbers of highly efficient cassava starch production line equipment and machines; Grinding the starch with the high-speed rasper. Then extract the protein by the machine called “Decanter”. Dry the cake in the flash dryer. This process requires only short period of time and provides superior quality of starch.

PREV:What determines the yield of cassava starch production line?

NEXT:What are our advantages of cassava starch production plant?

Leave a message about Two ways of cassava starch production line working method

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour