Potato starch processing plant

Date:

Date:

June 19, 2019

- WhatsApp:

- Tel:

- Phone:

- Email:

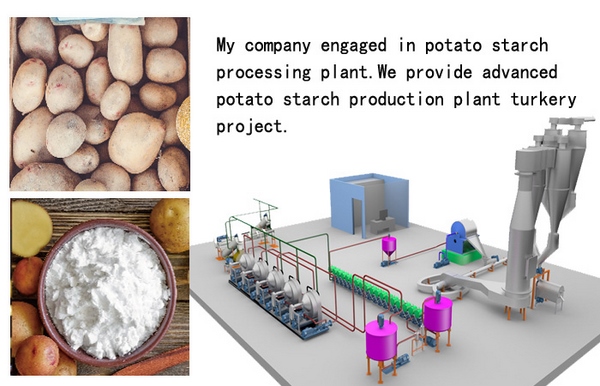

Potato starch is starch extracted from potatoes. The cells of the root tubers of the potato plant contain starch grains (leucoplasts). To extract the starch, the potatoes are crushed so that the starch grains can be released from the destroyed cells. The starch is then washed out to separate fiber and other impurities and then be dried in potato starch processing plant.

Then how to make the starch from potato? Here is the detailed introduction of potato starch making process in potato starch processing plant:

1- Sorting and weighing: First, we need to sort wholesome and health potato roots for starch processing. Then the sorted roots need to be weighed.

Potato starch processing plant

Potato starch processing plant

2- Cleaning & washing: This section in potato starch processing plant is mainly for clean away the debris attached on raw potato.

3- Crushing section: In potato starch processing plant, the peeled roots are grated to produce a smooth mash.

4- Extracting: The crushed potato mesh is sent to a centrifuge sieve to extract the starch.

Potato crushing machine

Potato crushing machine

5- Sedimentation: The starch milk is allowed to settle forming two layers i.e. the top free supernatant liquid and the thick starch slurry.

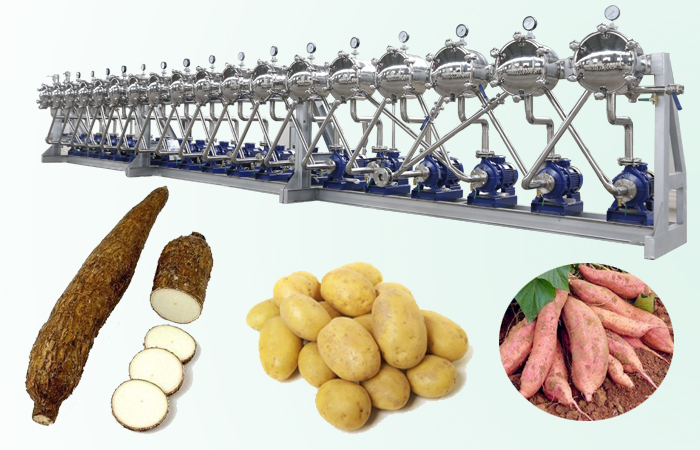

6- Concentration and refining unit: Then in potato starch processing plant, the starch milk from centrifugal sieve goes into the 16 stages of refining hydro-cyclone, and fresh water comes into the cyclone from the end of system.

7- Dewatering: The supernatant layer of liquid is removed by siphoning off the liquid with rubber hose and the thick slurry obtained is dewatered to reduce its moisture content.

Potato dewatering machine

Potato dewatering machine

8- Air drying unit of potato starch process plant: After dewatering process in potato starch processing plant, the air dryer will dry the starch to the required moisture of the commercial starch.

9- Milling: The dried product is milled to desired particle size (if necessary).

10- Packaging: The starch is packaged appropriately in potato starch processing plant.

Potato starch contains typical large oval spherical granules ranging in size between 5 and 100 μm, which is a very refined starch, containing minimal protein or fat. Therefore potato is a perfect raw material for starch processing. If you want to set up a potato starch processing plant and need more information about potato starch processing or equipment, weclome to contact Doing Machinery,our engineer will give you a feasibility potato starch processing plant program according to your requirement.

Leave a message about Potato starch processing plant

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour