Cassava flour production process

Date:

Date:

Aug 12, 2017

- WhatsApp:

- Tel:

- Phone:

- Skype:

elina881130

- Email:

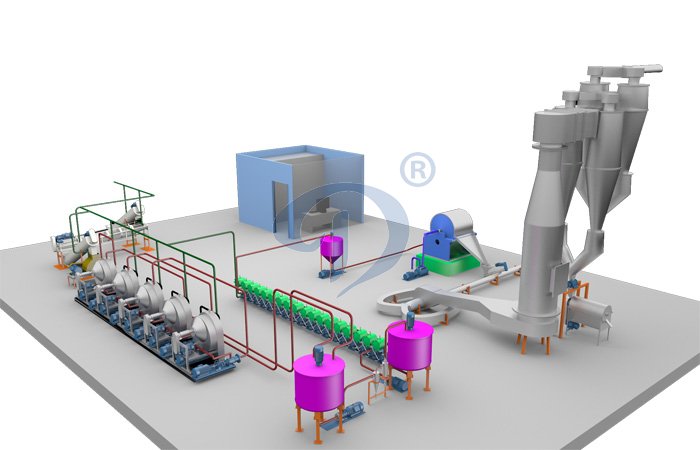

Cassava flour production process

Introduction of cassava flour production process, generally there are 6 steps during cassava flour production process. From Harvesting, washing and peeling, grinding, dewatering, drying, and packing.

Step 1: Harvesting the cassava tuber

Harvest matured cassava from the farm and load it to the cassava flour production process shed immediately. If the quantity of cassava harvested can not be carried in the same day for logistic reasons do not detach the cassava from the stem and leaf until the vehicle to carry it is ready.

Cassava washing and peeling machine

Step 2: Washing and peeling cassava during the cassava flour production process

Our cassava peeler could handling large capacity of cassava and well cleaning. This cassava peeler machine is with stable operation and easy maintenance etc. 1. peeling 2. washing 3. do not hurt the material 4. material to the next stage automatically.

Cassava grinding machine

Step 3: Grinding section in cassava flour production process

The tuber is grinded and become low broken percentage . That means 50% cassava flour is not separated and combined with fiber. In the rasping process, should add process water to dilute slurry. So the special design of rasper is vital for flour fineness and freeness.

Dewatering machine

Step 4: Dewatering

Because there is hydrocyanic acid toxic substance in cassava peels. In this unit, we use filter presser to dewatering and detoxification process.

When slurry reaches to certain liquid position in slurry tank, start to dewater by filter presser. Then transport the material to cassava flour drying procedure by belt conveyor.

Cassava flour drying machine

Step 5: Drying section for cassava flour production process

Dewatered cassava flour cake contains high moisture to 45~50%, which can’t enter into flash dryer directly and will be mixed with dry flour and reduce the moisture to 38%, then transported to feeding port of flash dryer by conveyer belt, pass through feeder and enter into raiser. The sieved cassava flour is transported to hopper for storing and cooling.

Automatic cassava flour packing machine

Step 6: Automatic Packing

1. Automatic weighing and calculating

2. Large adjustable weighing scope from 5-50kg

3. Hand seal, Packing cassava flour in different bags.

Above all is the simple description of cassava flour production process,to get more information of cassava flour production process,welcome to visit my factory,and my sales manager will offer you a nice program according to your demand for cassava flour processing plant.

PREV:Automatic complete cassava starch processing plant

NEXT:Introduction of cassava starch extraction production line