Starch disc separator

Date:

Date:

April 28, 2018

- WhatsApp:

- Tel:

- Phone:

- Email:

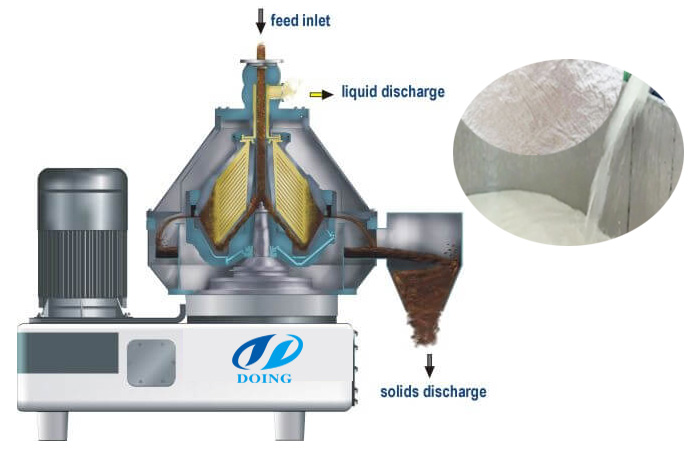

Cassava starch disc separator is a kind of settling centrifuge. And the machine plays an important part in the process of cassava starch processing line. The cassava starch disc separator mainly separates protein and cell liquid out of cassava starch slurry, and can be used for enrichment and purification of cassava starch slurry. usually, cassava starch disc separators are used in the cassava starch processing line in conjunction with hydrocyclone station. Most importantly, Doing cassava starch disc separator use centrifugal force to accelerate separating process, which contributes to the production of purer cassava starch slurry. Cassava starch disc separator can be manually open for check. The machine also has a complete sophisticated system that can separate protein and cell liquid effectively under the centrifugal force. Combined with hydrocyclone for starch processing can improve the process speed and starch quality.

Doing Companydisc separator

Cassava starch disc separator features:

1. The parts in contact with material are made of stainless steel, thus it can be resistant to corrosion and be reserved for a long time. Therefore, it also meets the requirement of food hygiene.

2. Frequency conversion startup, thus cassava starch disc separator runs stably with reliable operation.

3. The cassava starch disc separator has high rotating speed and high separating factor. So it can shorten the cassava starch processing time.

4. Comparing to other disc separators , Doing cassava starch disc separator consumes low power and water.

5. Disc separator has continuous discharging nozzle, which guarantees continuous operation.

Disc separator

Cassava starch disc separator working principles:

Cassava starch disc separator is a vertical centrifuge, the drum is installed at the top of the shaft. The machine is driven by the motor and rotates at high speed through the transmission device. Inside the drum is a set of discs that overlap with each other. There is a small gap between the disc and the disc. The material is added to the drum from a feeding tube at the centre of the drum. When the material flows through the gap between the discs, the protein and the cell fluid settle onto the disc of cassava starch disc separator to form sediment (or liquid layer) under the action of a centrifuge. The sediment slips along the surface of the disc and leaves the disc and accumulates in the position with the largest diameter in the drum. The separated liquid drains the drum from the outlet. The role of the disc is to shorten the settling distance and to enlarge the settling area of the drum. The production capacity of the separator is greatly improved because of the installation of the disc in the drum. Besides, the sediment accumulated in the drum are removed by manual removal after the cassava starch disc separator is shut down, or the sediment is discharged from the drum without stopping by the slag discharge mechanism.

Cassava starch disc separator parameters:

| Model | DYDP445 | DYDP520 | DYDP550 | DYDP800 |

| Capacity m3/h | 35 | 45 | 75 | 130130 |

| Material |

Stainless steel |

Stainless steel |

Stainless steel |

Stainless steel |

| Bowl diameter(mm) | 445 | 470 | 550 | 810 |

| Rotating speed(r/min) | 5100 | 5100 | 4500 | 3000 |

| Seperating factor | 6480 | 6900 | 6230 | 4950 |

| Power(kw) | 37 | 37 | 55 | 110 |

| Disc number(pcs) | 73-75 | 78 | 125 | 130 |

| Nozzle number(pcs) | 10 | 10 | 12 | 20 |

| Weight(kg) | 1500 | 1800 | 2100 | 4200 |

All in all , cassava starch disc separator is one of excellent cassava starch processing machines made by Doing company. In other words, Doing also provides a complete set of cassava starch processing machines, which contain cassava dry sieve and washing machine, cassava cutting machine , cassava crushing machine, cassava starch separating machines ,cassava starch dehydrating machine and drying machine, cassava starch packing machine. These machines all are designed with domestic techniques in combination with foreign advanced technology.

PREV:Nothing

Leave a message about Starch disc separator

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others