Cassava flour production

Date:

Date:

Sep 12, 2017

- WhatsApp:

- Tel:

- Phone:

- Skype:

elina881130

- Email:

My company developed edible cassava flour production line which aim at Africa local abundent cassava source. The newest food grade cassava flour production process solve daily staple food and develop cassava usage and processing.

Cassava flour & cassava

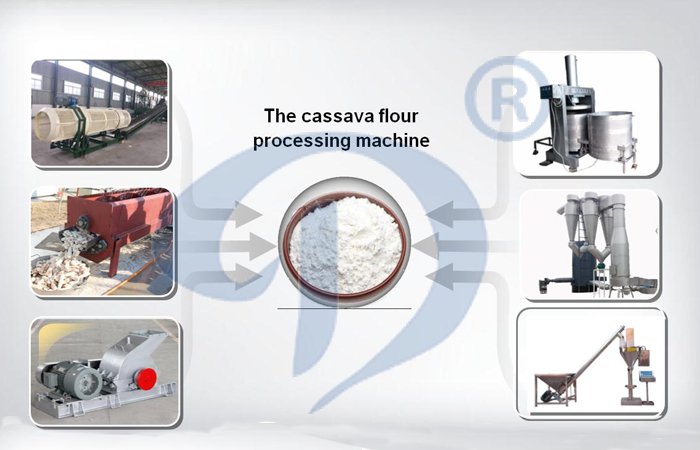

Main cassava flour production process detailed description as following:

Root reception and washing during cassava flour processing:

The fresh cassava roots are taken afield to the factory by truck. After being weighed and sampled for starch content determination the fresh roots will be unloaded to the raw material storage platform.

When production begins cassava roots will be washed and peeled by cassava peeling and washing machine.The main function is to removing the stone and other impurities. Dry cleaned the roots are sent to paddle washer for 3 stage water cleaning to get rid of remained sands and peeled skin.

Cassava peeling machine and cassava grating machine

Grinded and rasping unit during cassava flour production:

In the rasping process, should add process water to dilute slurry. the cassava slurry in the collection trough is pumped in to desanding cyclone. Don't make the cassava flour dissociate and make the cassava flour combine with fiber. So the special design of rasper is vital for flour fineness and freeness.

Dassava flour processing machine -- desanding unit

Desanding unit during cassava flour processing:

In the desanding unit, sands and sawteeth etc coarse particle will be removed from cassava slurry. This unit is made of ceramic cyclongnetts,sands collection tank,automatic desanding valve and back flush device.back flush avoid cassava flour loss in desanding process. Desanded slurry is sent to dewatering unit.

Cassava flour production machine -- detoxification and dewatering

Cassava flour detoxification and dewatering

When slurry reaches to certain liquid position in slurry tank, start to dewater by frame filter presser. Then transport the material to cassava flour drying procedure by belt conveyor.

Cassava flour drying machine

Drying and packing unit during cassava flour processing:

Dewatered cassava flour cake contains high moisture to 45~50%, which can’t enter into flash dryer directly and will be mixed with dry flour and reduce the moisture to 38%, then transported to feeding port of flash dryer by conveyer belt ,pass through feeder and enter into raiser. The heat source of flash dryer is steam heat exchanger. Wet cassava flour is heated by hot wind and water is steamed. After drying, cassava flour and air are separated in cyclone separator. At the bottom of cyclone separator, it is closed by air closer. after wet air leave cyclone separator , which is discharged in to atmosphere. Collected cassava flour is transported to vibration sieve unit; the coarse particulate matter is sieved out. The sieved cassava flour is transported to hopper for storing and cooling.

Cassava flour production machine

My company (Henan Doing Mechanical Equipment Co.,Ltd) can provide you the complete set cassava flour production plant machine and the technology support for cassava flour production plant.Welcome to email us for more information of cassava flour production line machine.