Balance Between Cost and Efficiency: Small-Scale Industrial Solutions for West African Garri Processing

Traditionally garri produced through arduous manual labor, scaling up to meet market demand while maintaining quality and profitability presents a significant challenge. For entrepreneurs entering this sector, striking the right balance between initial investment (cost) and production output (efficiency) is critical. A well-designed small-scale industrial garri processing line offers the perfect solution.

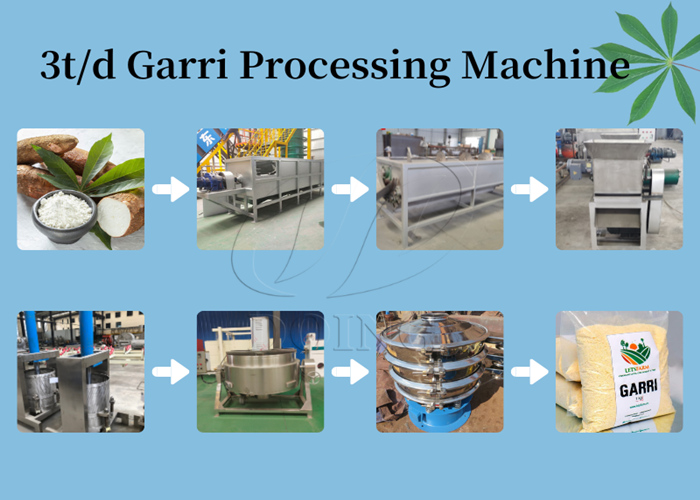

garri processing line

garri processing line

The Small-Scale Industrial Solution: Core Equipment for Success

A focused investment in essential garri processing machinery creates a powerful, yet accessible, entry point. A core line capable of processing 4 tons of fresh cassava roots per hour into approximately 1 ton of high-quality garri can be established with an investment between $20,000 and $30,000, depending on configuration and power sources. This garri processing line typically includes:

Cassava Cleaning Machine: Quickly clean and wash cassava tubers with less water to maintain food safety.

Cassava Peeling Machine: Replaces the labor-intensive and time-consuming task of manual peeling, significantly speeding up the initial stage and improving hygiene.

cassava peeling machine

cassava peeling machine

Cassava Grating Machine: Efficiently grates the peeled cassava into a fine mash, a crucial step far faster and more consistent than manual grating.

Garri Hydraulic Presser: Provides powerful and efficient dewatering of the grated mash. This is vital for removing excess water and achieving the right texture for frying. Hydraulic presses offer significant force and control compared to manual sack pressing.

Garri Frying Machine (Roaster): Ensures consistent, efficient, and controlled roasting of the dewatered mash. This directly impacts garri's final taste, texture, color, shelf-life, and safety, overcoming the variability of manual frying over open fires.

garri fryer

garri fryer

Vibration Sieving Machine: Achieves precise grading and separation of the roasted garri into uniform particle sizes (e.g., fine, medium, coarse). This enhances product quality, consistency, and market value compared to manual sieving.

Automatic Packing Machine (Optional but Recommended): Streamlines the final packaging stage, ensuring hygienic, accurate, and professional sealing. This improves presentation, shelf life, and branding potential.

The Cost-Efficiency Balance: Why This Setup Works

Significant Efficiency Gains:This garri processing line dramatically boosts output compared to manual methods. Processing 4 tons of cassava per hour (yielding ~1 ton garri) provides a solid foundation for a profitable business, supplying local markets consistently.

Manageable Investment: At $20,000-$30,000, the initial capital outlay is realistic for dedicated entrepreneurs, potentially funded through savings, loans, or investor partnerships. This is a fraction of the cost of large-scale garri processing plants.

garri machine

garri machine

Improved Quality & Consistency: Mechanization ensures standardized peeling, grating, dewatering, roasting, and sieving. This results in higher quality, safer (better cyanide removal), and more uniform garri, commanding better prices.

Reduced Labor Dependence & Costs: While some labor is still needed (loading, monitoring, packaging), reliance on large numbers of workers for strenuous tasks like peeling, grating, and pressing is drastically reduced, lowering operational costs and management complexity.

Scalability: This core garri processing line serves as an excellent foundation. As the business grows, additional units (like extra fryers or presses) or complementary equipment (like hammer mills for finer flour) can be added incrementally.

Starting with this balanced, small-scale industrial solution to garri, West African cassava processors can move beyond subsistence production, build viable businesses, contribute to food security, and drive sustainable growth.

Henan Jinrui, dedicated in making cassava processing machinery for over 10 years, is able to offer complete garri processing line for scaled flour production as well as individual cassava processing machine for small communities. If you have this demand, chat with us!

Leave a message about Balance Between Cost and Efficiency: Small-Scale Industrial Solutions for West African Garri Processing

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others