Production of starch from potato process

I. Overview of raw materials:

The potato are cobblestone-like, and the number and thickness of potato tubers of different varieties vary greatly. The potato has a high starch content, contains less protein and fat, and has a starch content of 15 to 25%. So potato is a good raw material for starch production. Some of the unique properties of potato starch are irreplaceable by other starches and are widely used in the food industry.

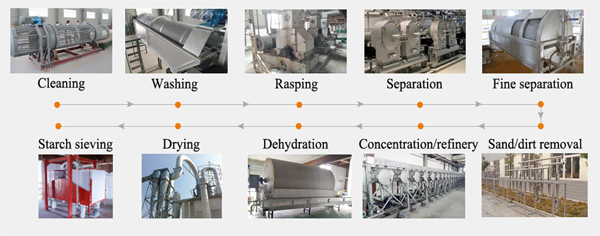

Ⅱ. The production of starch from potato process brief:

Potato - Soaking and Conveying - Cleaning and Transportation - Second degree Cleaning - Crushing - Separation - Desanding - Concentrated&Refining - Vacuum Dewatering - Drying - Sieving - Finished Packaging

Production process of potato starch and main machines

Production process of potato starch and main machines

Ⅲ. Production of starch from potato process details and equipments:

1. Cleaning process and equipment:

The main purpose is to remove the sediment from the outer skin layer of the potato and wash away the skin of the root of the potatoes. The dry sieve machine is to remove the hard impurities in the material. Then the rotaty washer will further washing the potato. Cleaning the raw material for starch production is the basis for ensuring the quality of the finished starch. The cleaner the cleaning, the better the quality of the starch.

Commonly used conveying, cleaning and stone removal equipment are: water flow tank, screw cleaning machine, oblique squirrel cage cleaning machine, paddle cleaning machine, stone removal cleaning machine, (flat) squirrel cage cleaning machine, rotating drum type washing machine, scraper conveyor, etc., according to the soil and material characteristics, some of them can be combined to achieve high cleaning purity and convenient transportation in the starch processing plant.

Potato cleaning machine

Potato cleaning machine

2. Raw material crushing process and equipment:

The purpose of the crushing step for production of starch from potato process is to destroy the structure of the potatoes, so that the tiny starch granules can be smoothly separated from the potato roots. The requirements for crushing are:

A. As much as possible to break the cells of the potato, releasing more free starch granules;

B. Easy to separate. It is not desirable that the skin residue is too fine, and the skin residue is too fine to separate the starch from other components, which in turn increases the difficulty of separating the fine residue.

DOING Rasper - for potato crushing

DOING Rasper - for potato crushing

3. Separation process and equipment

Starch extraction, also known as slurry-residue separation, is a key link in production of starch from potato process, directly affecting starch extraction rate and starch quality. The pulverized material is fine fiber, volume is larger than the starch granule, the expansion coefficient is also larger than the starch granule, and the specific gravity is lighter than the starch granule. The pulverized material(fiber) is separated from the starch by using water as a medium. This step of production of starch from potato process adopt the centrifuge sieve&fine fiber sieve to complete, get a ideal separation effect.

Centrifuge sieve from Doing Company

Centrifuge sieve from Doing Company

4. Concentrated&Refining process and equipment

The washing and concentrating of the starch is carried out by means of a starch cyclone, which is divided into a concentration cyclone and a washing refining cyclone. After the sieving, the starch slurry passes through a concentration cyclone, and the bottom stream enters the washing and refining cyclone to finally meet the product quality requirements. The equipment is equipped with a complete automatic control system, using high-quality swirl tube and optimized piping scheme for production of starch from potato process, which can make the concentration of starch milk in the last stage cyclone reach 23Be', which is an ideal choice for starch washing, concentrate, refining equipment.

Potato starch processing

Potato starch processing

5. Starch dehydration

Potato starch is often used the vacuum filter dehydrator. Automatic feeding, automatic dehydration, and automatic cleaning are possible. Now this is the first choice for potato starch processing plant in the starch dehydration step.

6. Starch drying

The flash dryer uses a high-speed flowing hot air stream to suspend the wet starch therein and dry it during the flow of the air stream for production of starch from potato process. Doing Company flash dryer has the characteristics of high heat transfer coefficient, large heat transfer area and short drying time.

Vacuum filter

Vacuum filter

7. Starch cooling, sieving and packaging

After the starch is dried, the temperature is high. To ensure the viscosity of the starch, the starch needs to be rapidly cooled after drying in the production of starch from potato process. DOING factory adopts cold air system, which has the advantages of low energy consumption, good cooling effect, stable operation and large processing capacity. The cooled starch enters the finished sieve and enters the final packaging process on the premise of ensuring product fineness and yield.

The starch slag produced in small factories is directly used as feed without drying, while the starch slag in large factories is mostly dry. In order to save heat energy, it can be dehydrated by a scress press dewatering machine and then dried by a air dryer. Except the complete set of potato starch processing equipment, Doing Company also supply the scress press dewatering machine.

Potato starch processing plant overview

Potato starch processing plant overview

Ⅳ. the main indicators:

This potato starch production line can processing fresh potatoes 50-150 tons per day.

Potato raw material requirements: starch containing > 15%, fresh, no mold, no soil, no stones.

Water supply requirements: turbidity <0.1, hardness <100, SO2 <0.55ppm, iron <0.9 ppm, no floating matter, pressure >0.2MPa.

The standard of finished potato starch: moisture ≤ 18 ~ 20%, fineness ≥ 99.6, protein ≤ 0.1%, whiteness ≥ 90% (475mn, reflectivity), chemical SO2 ≤ 30ppm, ash ≤ 0.25, The spots are ≤3. (fully in line with national first-class standards)

Water consumption: 2~3T per ton of fresh potato

Power consumption: about 200 degrees consumption per ton of finished potato starch

Coal consumption: about 2 tons of steam consumption per ton of finished product

Doing Company starch sieving machine

Doing Company starch sieving machine

Ⅴ. Civil construction requirements

The main workshop for production of starch from potato process can adopt steel frame structure, the building area is about 400m2, the height is more than 4m, the part is 13m, the raw material warehouse, finished product warehouse, and product warehouse are not included. The auxiliary room and office building are self-determined. The total area of the factory is not less than 2000 square meters.

Leave a message about Production of starch from potato process

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour