Common Problems in Drying Cassava Flour and Starch by a Flash Dryer

Flash drying is a cornerstone of efficient cassava processing, prized for its rapid moisture removal and ability to handle heat-sensitive cassava flour and starch. However, the drying process presents significant challenges that can compromise flour integrity and economic efficiency. Next Henan Jinrui will post these problems to you for ensuring smooth production.

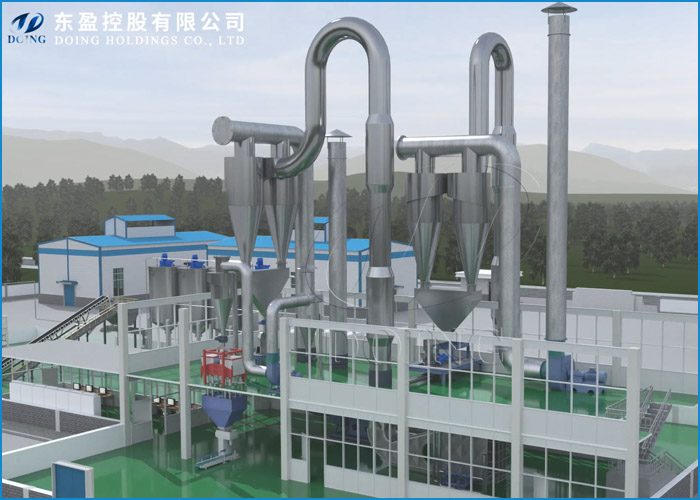

flash dryer

flash dryer

1. Inconsistent Feed Material: Instability at the Source

The quality of the wet cassava cake entering the flash dryer fundamentally dictates success. Key issues include:

Variable Moisture Content: Inconsistent dewatering leads to cassava cakes that are either too wet (overloading the flash dryer, causing lumps, uneven drying, and high energy use) or too dry (risking particle bypass or overheating). Both extremes disrupt efficiency and final flour quality.

Lump Formation: Poorly broken wet cassava cake forms lumps. These dry only on the surface, trapping moisture inside, reducing drying efficiency, and potentially causing blockages.

Irregular Particle Size: Wide cassava flour and starch size variations result in uneven drying. Small cassava particles dry instantly, while larger ones may retain moisture, especially problematic for cassava starch requiring precise low moisture levels for functionality and storage.

one-staged cassava powder dryer

one-staged cassava powder dryer

2. Thermal Degradation: Protecting Sensitive Materials

Cassava flour and starch are vulnerable to heat damage:

Discoloration (Yellowing/Browning): High temperatures cause cassava starch degradation or Maillard reactions (in cassava flour, between proteins and sugars). This downgrades product quality and market value.

Loss of Functionality: Overheating, particularly cassava starch, damages molecular structure, altering critical properties like viscosity, solubility, and gel strength, making it unsuitable for target applications.

3. Moisture Control Imbalances

Achieving precise final moisture is critical:

Over-Drying: Excessively low moisture wastes significant energy, increases brittleness (generating fine flour), risks thermal damage, and worsens dust/static issues.

Under-Drying: Residual moisture above 13-14% invites disaster: rapid microbial growth (mold, bacteria, mycotoxins), caking and lumping during storage, and drastically reduced shelf life.

two-staged cassava powder dryer

two-staged cassava powder dryer

4. Starch vs. Flour: Key Processing Differences

Cassava Starch: Higher thermal sensitivity demands tighter temperature control. Uniform cassava starch particle size is essential for functionality. Requires ultra-strict contamination control. More prone to fines generation.

Cassava Flour: Less heat-sensitive than starch but more susceptible to Maillard browning. Fibrous content promotes flour lumps and worsens flowability. And fine flour remains highly explosive.

Essential Solutions for Successful Drying

Optimize Pre-Drying: Ensure consistent dewatering (35-45% moisture) and use effective lump breakers/screening. Normally a plate-frame filter press and a peeler centrifuge will be added in the cassava flour and tapioca starch production line respectively to remove most of water.

Precise Process Control: Rigorously manage inlet/outlet air temperatures, airflow, feed rate, and residence time using automation and real-time sensors (moisture, temperature).

Thermal & Moisture Management: Use minimum effective temperatures to dry cassava flour and starch. Integrate immediate post-dryer cooling. Set appropriate moisture targets (Cassava Flour: 10-12%, Cassava Starch: 12-14%).

Fines Management: Optimize air velocity and cyclone efficiency; consider fines recycling if quality permits.

Avoiding these problems, the flash dryer can improve the quality of cassava flour and starch. If you want to get consistent flour to meet market demand, feel free to chat with us! Henan Jinrui's professional manager will suggest you whether configure one-stage or two-stage dryer!

PREV:8 Factors to Consider When Buying Potato Starch Processing Equipment

NEXT:Construction and Economic Analysis of Establishing Cassava Processing Plant in Africa

Leave a message about Common Problems in Drying Cassava Flour and Starch by a Flash Dryer

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others