Industries production process of cassava flour for bakery

Recently years, Nigeria and many other cassava production countries start promoting the use of cassava flour in the bakery, It has demonstrated that the bread made from cassava flour instead of 10% wheat flour is sweeter and healthier. Therefore, bakery demand quantity for cassava flour has been increased large, industries production process of cassava flour for bakery highly concerned. For another, industrial cassava flour production process can get higher quality cassava flour, taste better, more suitable for cassava flour used for bakery. And industries production process of cassava flour can get large output, because of the advanced technology and professional cassava flour making machines adopted.

Bread make from cassava flour

Industries production process of cassava flour for bakery received more and more attention, goverment, businessman, investor, cassava grower, etc., the high quality cassava flour is simple unfermented cassava flour. The desire to reduce dependence on importation and conservation of foreign exchange has increased the Federal Government’s drive to source for local alternatives to the processing of cassava for flour, wheat flour substitution becomes utmost priority especially with the price of wheat in the international market is becoming unbearable. Businessman and investor see the business opportunity from the development of industries production process of cassava flour for bakery.

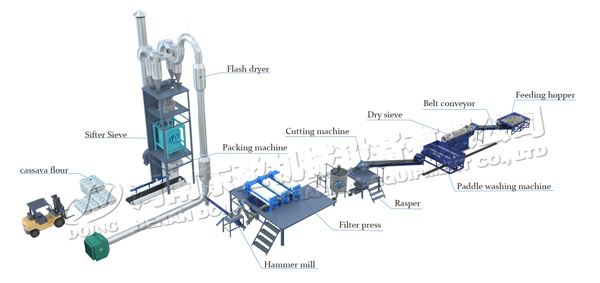

DOING company is a professional cassava processing machine manufacture and supplier, we have been installed many cassava flour processing plant for our customer in many area, which equipped with modern industries cassava flour production machines. Here is the main steps of industries cassava flour production process from Doing Company:

DOING company designed cassava flour processing plant

The first step is cleaning and washing, dry sieve can remove dirt, sand and small stones. According to the multi-screw operation, the blade cleaning machine can remove the sediment and impurities on the surface of cassava. At the same time, the outer skin of cassava can be simply disposed of. This is the first step of the industries production process of cassava flour for bakery. If the client want small scale, the step can be replaced by labor.

The second step is crushing: cassava rasper is a high efficient cassava rasper. Because of the centrifugal force, the blade and clamping device are thrown to the outer edge.The cassava are then ground up with file shards and tooth flakes. Large crushing capacity, strong production capacity, uniform product size, low energy consumption, simple structure, light weight, convenient operation and maintenance, high toughness. All the above is the advantage of the rasper.

DOING company cassava flour making machine

The third step of the processing of cassava for flour is slurry de-sanding: cassava slurry is pumped into the cyclone de-sanding machine. The impurities will be separated and collected into a container discharging. For industries production process of cassava flour for bakery, bescause of rasper machine higher crushing performance, together with the desander to remove impurities, the produced cassava flour can remove the toxin from the cassava skin, this is a new cassava flour processing method, can get better economic benefit, finished cassava flour quality higher than before.

The fourth step of the processing of cassava for flour is pressing: plate and frame filter press is a dewatering machine which utilizes pressure to remove the liquid from a liquid-solid slurry. A plate and frame filter press is the most fundamental design, this type of filter press consists of many plates and frames assembled alternately with the supports of a pair of rails. When the separating chamber is full, the filtration process is stopped as the optimum pressure difference is reached. The solids remain in the void between the plates, until the plates discharge the filtered solids.

The fifth step is milling: after dewatering, the cassava flour will be cassava flour cake. It is not convenient to dry. So the cassava flour cake will be milled by hammer mill. During the industries production process of cassava flour for bakery, hammer mill also can be taken by other type crushing machine.

The sixth step is drying, flash dryer is the last step of making cassava flour. Since the flash dryer adopts negative pressure and cooling system, cassava flour can be dried completely. The machine is key to the processing of cassava for flour.

The large production enterprises of cassava flour in African countries are few and far between. The future development of cassava flour production can be imagined. So the market of the industries production process of cassava flour for bakery is very promising. And Doing company will provide best machines and professional team if you plan to start a cassava flour processing business.

Leave a message about Industries production process of cassava flour for bakery

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others