What is process of starch extraction from cassava ?

The complete cassava extraction machine

What is process of starch extraction from cassava ?There are 12 main processes of starch extraction from cassava as following:

1.Raw material cleaning section during the starch extraction from cassava

Fresh cassava root is input into the drying cleaner of soil-removing and peeling in which screw guide plate fixed on inner wall of the cylinder cage pushes forward cassava root when the cylinder cage rotates. Cassava roots collide and rub themselves and also against the wall one another to remove soil and peel of under the centrifugal force. After soil-removing and peeling of cassava roots go into the agitation water cleaner.

Cassava cleaning machine

2.First step of water cleaning section during the starch extraction from cassava

U-tank water cleaner with screw propeller is used in the first step of water cleaning. Water goes into the U-tank in which a shaft with screw propeller is equipped. Cassava roots are agitated turned around the shaft and propelled forward to clean soil and peel again. Then Cassava roots go into the second step water cleaning.

3.Second step of water cleaning section during the starch extraction from cassava

Cylinder cleaner is used in the second water cleaning. The cylinder cleaner consists of 3 clearing sections: rough washing , bathe washing and thorough washing ,where water is fed and cassava roots run along with the cylinder and go ahead to further eliminate soil and peel in the status of spaying ,flushing bathing rubbing and cleaning. Water, as a cleaning media, is used at the rate of 1 : 4 . After cleaning thoroughly soil, 95% of peel is removed, the cleaned cassava roots move to crushing section.

Cassava crushing machine

4. Crushing section during the starch extraction from cassava

This crushing section adopts hammer crusher which destroys the tissue of cassava and makes the very small granular of starch decompose and depart from the roots.This step of crushing process is applied for full breaking down cassava root tissue which becomes finer granular of starch that separates thoroughly to increase the extraction rate.

5.First stage separation section, there are two stage separation section during the cassava starch extraction process.

First stage separation section utilizes 4 upright continuous centrifuges which separate starch milk from coarse cassava residue in 3 steps and fine residue in 1step sequentially(See production flow sheet). Starch milk is washed again and again and separates from cellulose (mostly cell wall).

Cassava starch extraction machine

6.First stage separation section

Starch milk after sieving by centrifuge in the first step and the second step is delivered to fine basket sieve in upright continuous centrifuge in which starch milk is further sieved from the more finer cellulose to be pure starch milk that contains fiber less than 0.02% and reaches 5~6 Bé in concentration. Coming out from the fine basket sieve in the centrifuge, starch milk goes to the filtration section while some dilute starch juice returns to the centrifuge in the first step for recycling sieving. A little of un-fully breached down material drained out from the centrifuge in the third step reflows to the crusher in the second step for circulating and cassava residue is carried to pile ground.

Cassava starch processing machine

7.Sand-removing procedure section during the starch extraction from cassava

Cyclone separator is used in sand removing procedure. Starch milk is pumped into the cyclone separator of which starch milk is shed out from the top and sand is discharged from bottom because of the principle of gravity. After sand-removing, starch milk proceeds to filtration procedure.

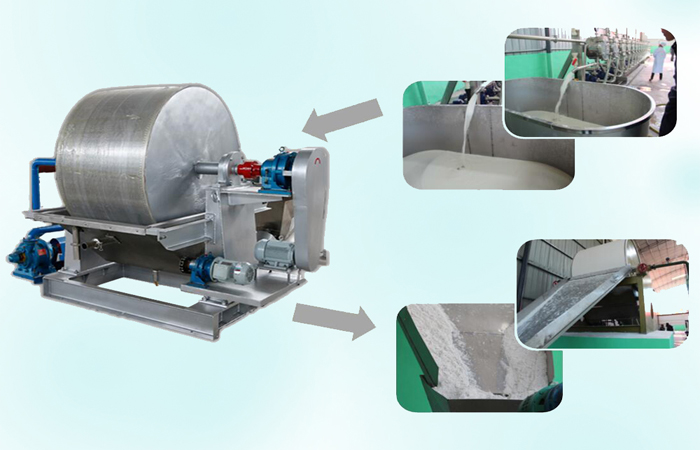

8.Filtration procedure section during the starch extraction from cassava

Rotary filter is applied in filtration process in which impurities is further cleaned out to ensure that no block happens to the latter process equipment. Impurities is retained by filtering drum and carried to the bottom of filter by hair brush, then discharged when starch milk is input into the filtering drum. After filtration, starch milk flows out from pipe which connects to the second stage of separation section.

9.Second stage separation section during the starch extraction from cassava

This stage includes 2 steps in which butterfly separator is provided to divorced insoluble protein and the remaining soluble protein and other impurities from starch milk following to the principle of gravity disparity of water, starch and protein of yellow juice aiming at washing , refining and concentrating of starch milk. Starch milk is 5~6 Bé in concentration for input while 20~22 Bé for output. After 2 steps separation in the second separation section, the concentrated starch milk is fed into dewater procedure.

Cassava starch extraction machine

10.Dewater procedure section during the starch extraction from cassava

Blade discharge centrifuge is served for dewater procedure in which water in the concentrated starch milk is thrown out to facilitate drying. Water content in the wet starch after dehydrated must be lower than 38%. The dewatered wet starch is moved to drying and cooling section.

Cassava starch extraction machine

11.drying and cooling section during the starch extraction from cassava

Air dryer is installed in the drying and cooling system where the dewatered wet starch is dried. The feeder inputs the wet starch into the starch projector which casts the wet starch into the drying pipe where the fresh air after being heated by heater mixes with the wet starch which is suspended on hot air flow and finally dried by means of heat-exchange in the process of substance transmission because of the strong back pressure resulting from the pneumatic effect of the blower.

12.Packing procedure

Pack the fine powder of starch from the outlet 1of the hopper into bag. Transport the starch product bag into the storage house.

Above all is the description of detailed process of starch extraction from cassava and the function of each starch extraction from cassava process.We can provide you the high quality equipment of starch extraction from cassava.

Leave a message about What is process of starch extraction from cassava ?

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others