Sweet potato starch production plant

Date:

Date:

January 18, 2023

- WhatsApp:

- Tel:

- Phone:

- Email:

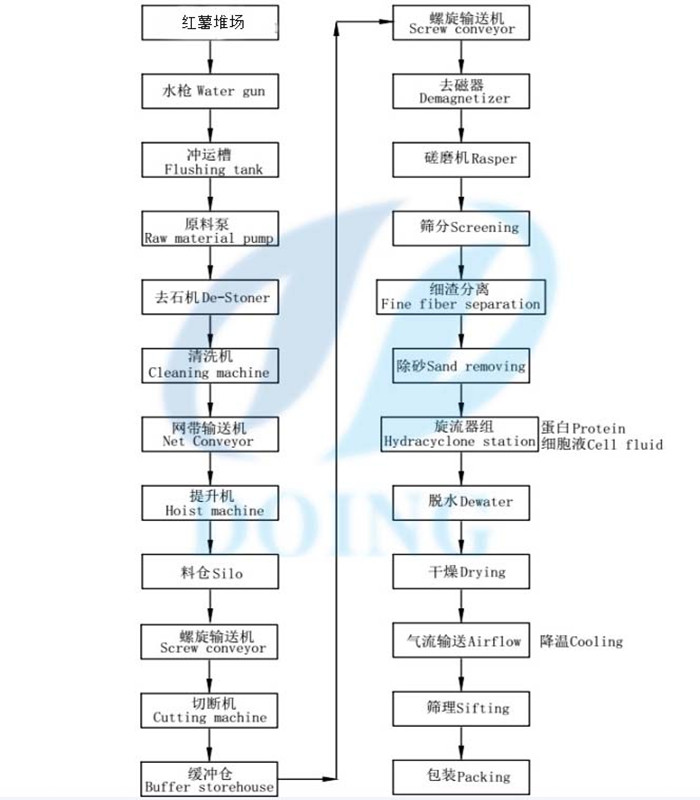

Sweet potato starch is produced from sweet potato through the process of cleaning, washing, crushing, fiber separating, starch refining, dewatering, drying, and sieving. Henan Jinrui company is a professional manufacturer and supplier of sweet potato starch production plants. The article will introduce process technology and equipment for sweet potato starch production plants.

Sweet potato statch processing process

Sweet potato statch processing process

Sweet potato starch production plant mainly consists of three parts: cleaning, processing, and drying.

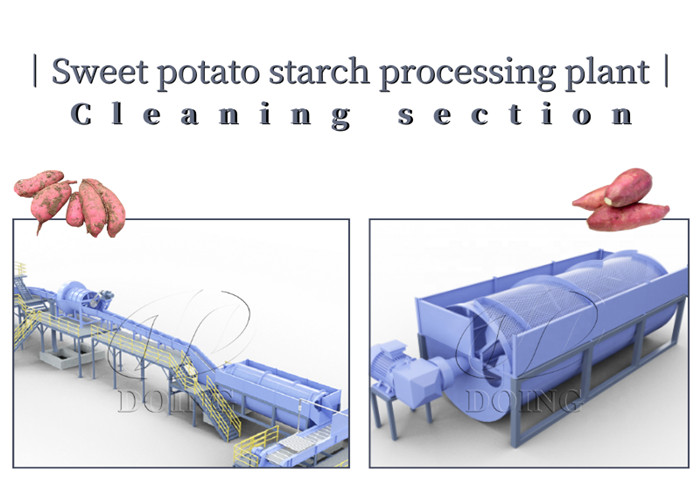

Cleaning section

First, the fresh sweet potato yard is usually flushed to the sink under the action of a high-pressure water gun, and then into the drum washing machine inside the workshop. In the process of hydraulic transmission, the purpose of transportation and cleaning can be realized. And De-stoner will be installed before the drum washing machine, to remove heavy stones or stuff. The drum washing machine has the advantage of large capacity and good cleaning effect.

Cleaning section of sweet potato starch production

Cleaning section of sweet potato starch production

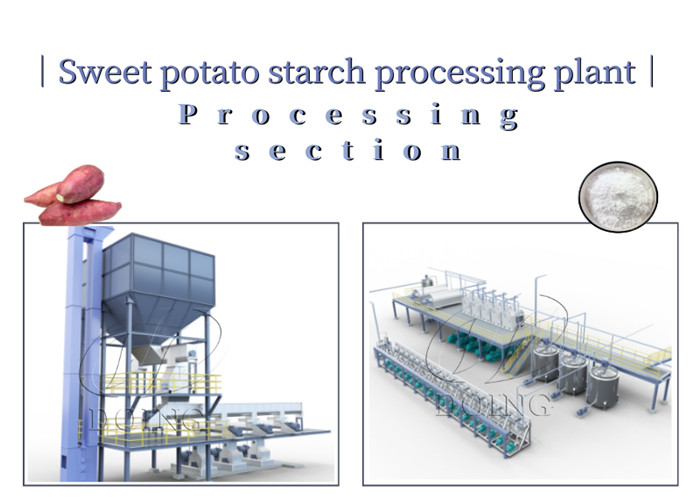

Processing section

The processing section is the key part that greatly influences the starch extraction rate. Cleaned sweet potato firstly will be elevated into a big silo for short storage. And then sweet potatoes were conveyed to a cutting machine for first crushing, and finally completely crushed by a rasper machine. Rasper has a high crushing effect, ensuring that almost starch particles can be released as much as possible.

After crushing, sweet potato mash will be pumped into a centrifuge sieve machine to separate fibers, then to a fine fiber machine to remove tiny fibers, to the de-sander machine to eliminate sands, and finally to a hydrocyclone station to remove liquid foreign contents like cell liquids and protein.

Processing section of sweet potato starch production

Processing section of sweet potato starch production

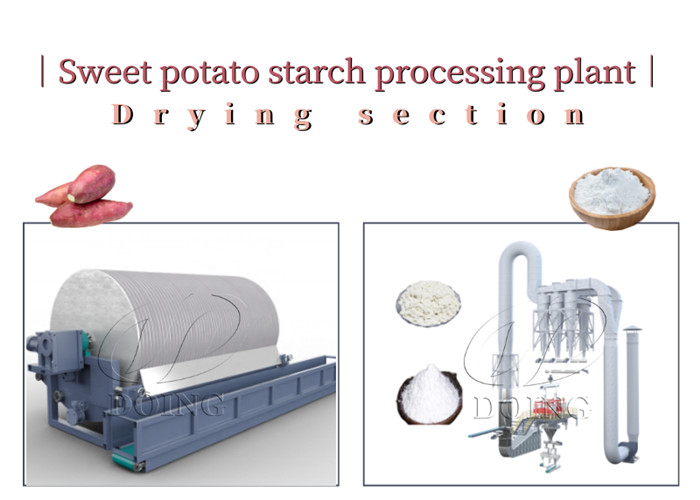

Drying section

The drying parts consist of dewatering, drying, and sieving. After we get purified starch milk in the processing section, the starch slurry will be pumped into a vacuum filter machine for dewatering, from which we can get wet sweet potato starch powder with a moisture of around 40%. And then wet starch powder will be sent into the flash dryer for complete drying. According to the national standard, dried starch moisture content should between 14-15%. The flash dryer supplied by Henan Jinrui can meet the standard. To meet higher fineness standards, a sieving machine will be installed after the dryer.

Drying section of sweet potato starch production

Drying section of sweet potato starch production

The above is a brief introduction to the sweet potato starch production plant from Henan Jnrui company. If you have the plan to set up such a plant, feel free to contact us any time.

PREV:Nothing

Leave a message about Sweet potato starch production plant

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour